Global market

Surfactants: Facts and figures

Many everyday products contain surfactants. The global market is changing – an overview.

Dishwashing detergents

The potential of biosurfactants

The Unilever expert Bert Nijhuis about rhamnolipids and environmentally friendly products.

Biosurfactants

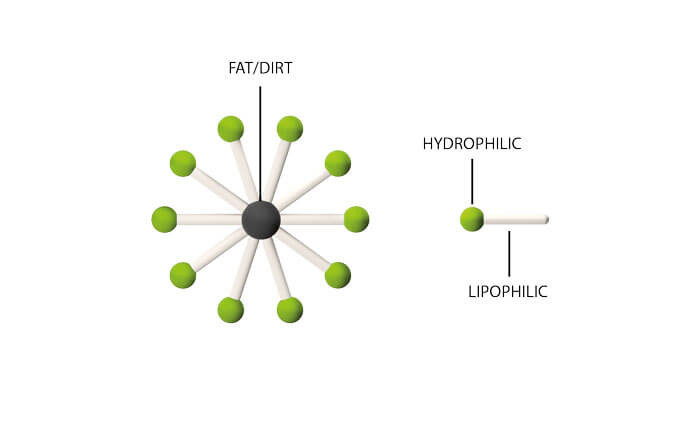

A clean sweep

Surfactants ensure that dishwashing liquids and shampoos do a thorough cleaning job. One particularly efficient class are biosurfactants.

Chemical production

Disinfection – what does it mean?

Disinfection puts dead or living material in a state where it can no longer infect. What does this mean in practice?

ELEMENTS Newsletter

Get fascinating insights into the research Evonik is conducting, and its social relevance, by subscribing to our free newsletter.