Foresight

Waste plastic as a sustainable resource

Old sportswear as material for new sneakers: Plastic waste can be reused in a sustainable way.

Lightweight and resilient

Multi-talented plastic

Lighter than steel, flexible, corrosion-resistant: three reasons for the success of polyamide 12, underground and in your car.

Pharma Polymers

Healing bones with polymers

The Medical Devices Project House is developing materials that support bone healing and make follow-up operations unnecessary.

Synthetic fibers

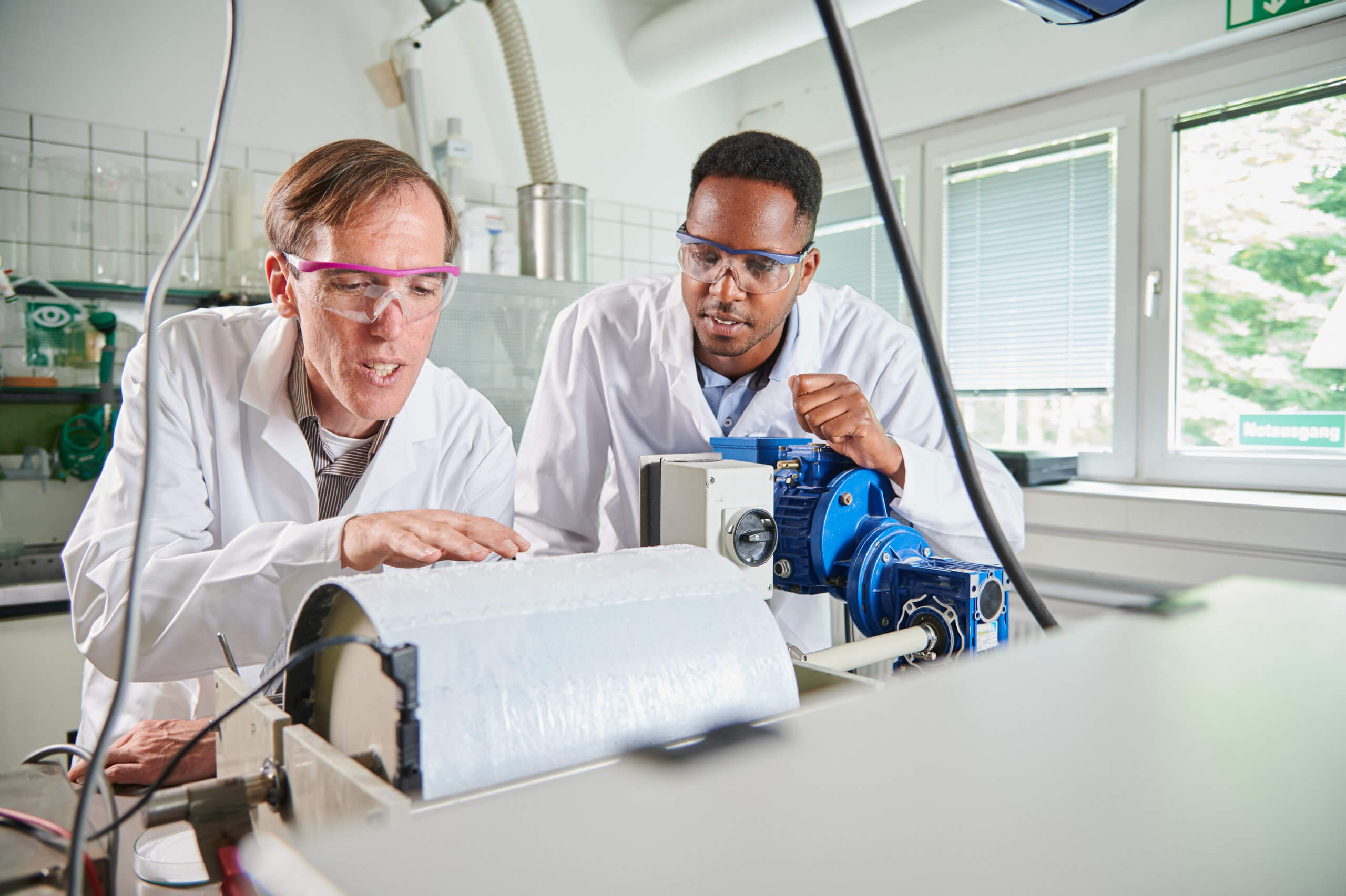

Hightech Membranes from Lake Atter

Membranes that could revolutionize the processing of natural gas are being made in the municipality of Schörfling in Upper Austria.

ELEMENTS Newsletter

Get fascinating insights into the research Evonik is conducting, and its social relevance, by subscribing to our free newsletter.