A component that is reinvented for 3D printing often has little in common with the original part. Whereas an injection-molded part has to be heavy and massive so that it can withstand great stresses, an equivalent 3D-printed part can have a seemingly filigree design consisting of arches, struts, and honeycomb structures. It can withstand stresses just as well as the injection-molded part but weighs only a fraction as much. As a result, even as simple a part as the window guiderails of a roadster give us a preview of how entire automobiles will be built in the future.

LIGHTWEIGHT PARTS FOR FLYING OBJECTS

These weight reductions make additive manufacturing a very interesting technique for aircraft construction. Every gram counts in this sector, and there is a rising demand for more fuel-efficient machines that are less damaging to the climate. The innovations of additive manufacturing are initially inconspicuous here as well. The US Air Force, for example, uses 3D printing to produce replacement parts for its veteran jet planes. The fact that 3D printing made a toilet seat much lighter but still robust thanks to the use of a honeycomb structure was considered newsworthy within the sector. The components that are being developed by the aircraft manufacturers Boeing and Airbus are more critical to an airplane’s operation. Metal powders are now being used to make the first wing and engine components, and the 3D printing of plastic parts is becoming increasingly common for cabin furnishings. In this case, it would often also be too expensive to create injection-molded parts—for example, when an airline modernizes its fleet. Such tasks require the expertise of specialists like the Belgian company Materialise, which, among other things, uses high-performance polymers to print components for Airbus.

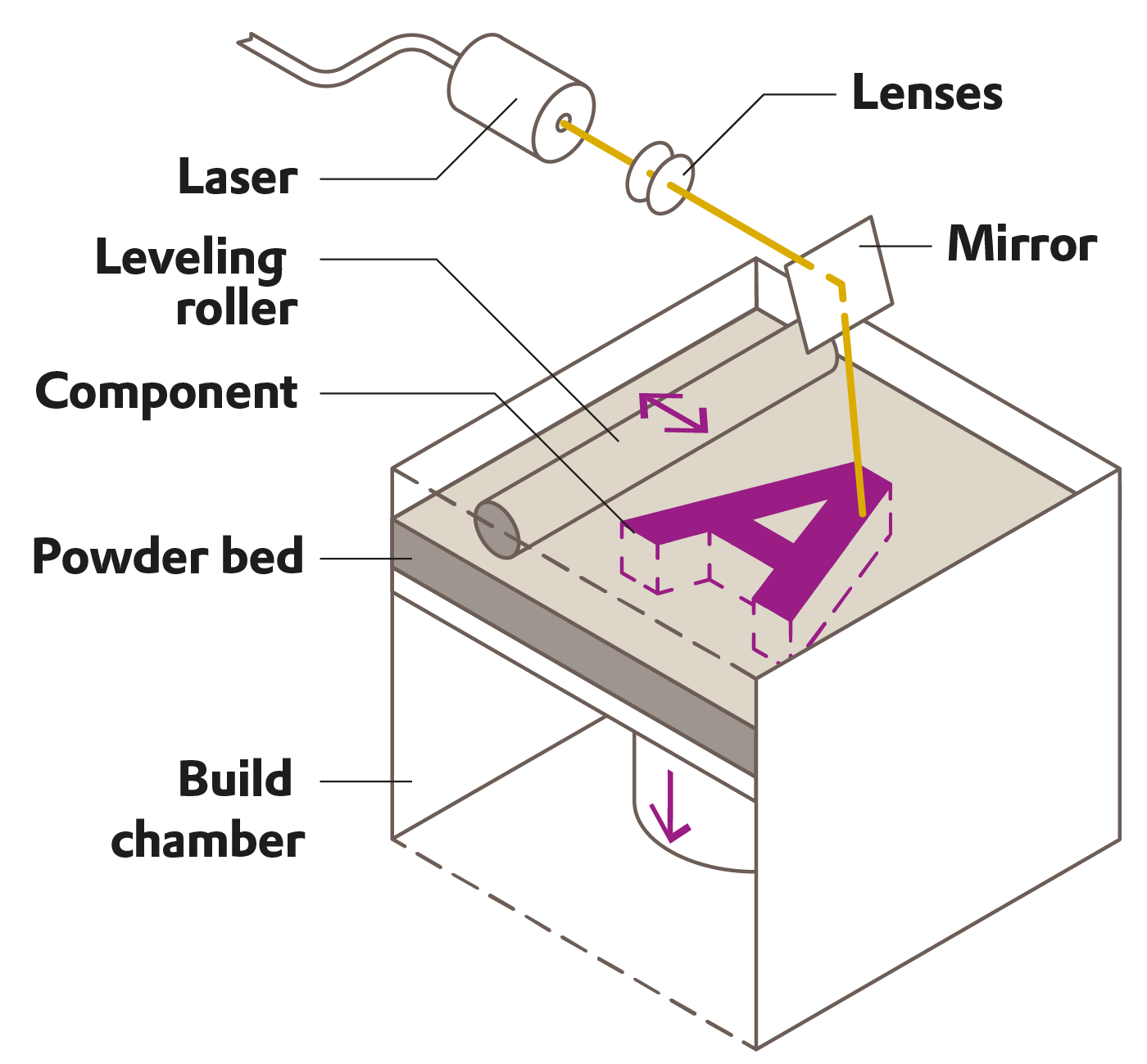

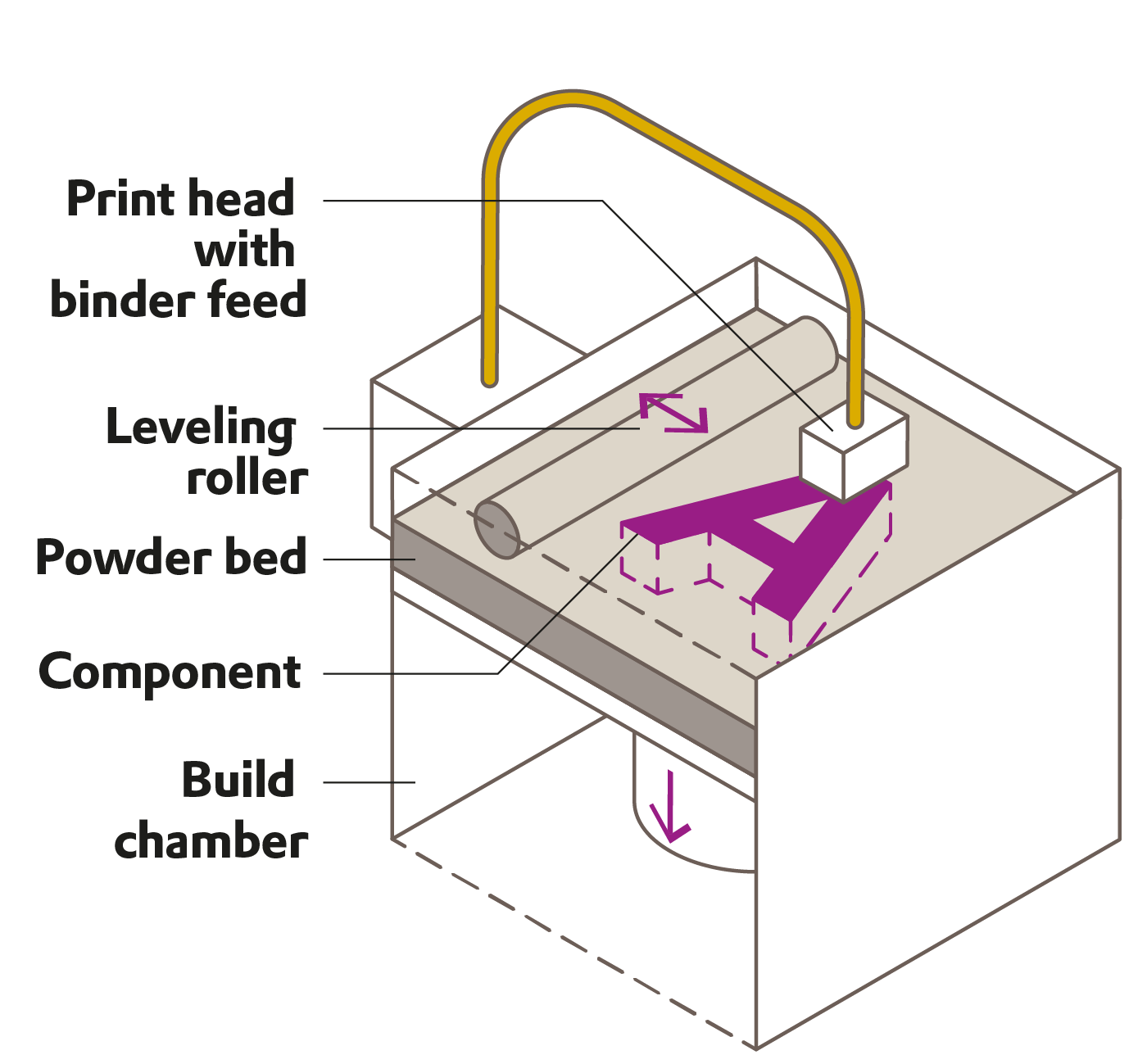

According to Monsheimer, greater production volumes will, more than anything else, require additive manufacturing to become faster. “The process will become especially interesting for the automotive industry when we begin to produce tens of thousands or hundreds of thousands of units,” she says. The new partnership between Evonik and the US startup Evolve (see the overview on page 15) might be the key to unlocking this potential. The startup’s technique, which is known as STEP, basically works like a laser printer and thus achieves much higher speeds. “Conventional powder-based processes always us a laser or print head that traces the print shape on the powder bed,” explains Innovation Manager Wolfgang Diekmann, who heads the 3D printing lab in Marl. “STEP, on the other hand, uses digital printing technology. The material is very quickly picked up by a drum, which then deposits it. Because the powder is very fine, the resulting component has a higher resolution than would otherwise be the case.”

“We have to completely redesign parts for 3D printing”

HEAD OF THE ADDITIVE MANUFACTURING INNOVATION GROWTH FIELD AT EVONIK

Evonik is contributing its decades-long experience with materials to the partnership, creating a win-win situation in the process, says Monsheimer. “We can develop new materials when we have a machine that we can test them with. Our partners, in turn, can develop a new machine when they have access to good materials,” she adds. As a result, the technical center in Marl is a veritable exhibition of the international 3D printing sector. In addition to machines from HP and 3D Systems, the center has devices from the German market leaders EOS and Voxeljet, the Swiss company Sintratec, and the Chinese manufacturer TPM. The devices are extensively used, as is demonstrated by an opened printer that Monsheimer is inspecting. “We want to know not only which materials we can develop for existing technologies but also how the existing technologies might be made better,” she says.

A Futuristic Quartet

New technologies require new partnership models. Evonik is cooperating with other companies worldwide in order to investigate promising future applications for 3D printing. Here are four examples

Artificial Bones

Artificial cranial implants, joints, and bone sections: “Nowhere else are the possibilities of 3D printing coming into their own as much as in medical technology,” says Marc Knebel, who manages the medical business at Evonik’s High Performance Polymers Business Line. “A customized product is created for each and every patient.” In 2019 Evonik became the lead investor in one of the sector’s most promising startups: the Chinese 3D printing specialist Meditool. The company, which is based in Shanghai, prints cranial, facial, and mandibular implants out of PEEK. This is a high-performance polymer that Evonik sells under the brand name VESTAKEEP®. Evonik was the first manufacturer to launch this plastic on the market as a medical-grade product. Meditool’s long-term goal is to grow in an even more ambitious segment: implants for spinal disc surgery. One of the first products it has developed for this purpose are cages—artificial intervertebral discs with which body tissue grows together. Evonik and Meditool now want to jointly determine how the research and practical clinical work in this area are developing. “Meditool offers a unique combination of technical competence and clinical expertise,” says Knebel. “We can help this company expand its global footprint.”

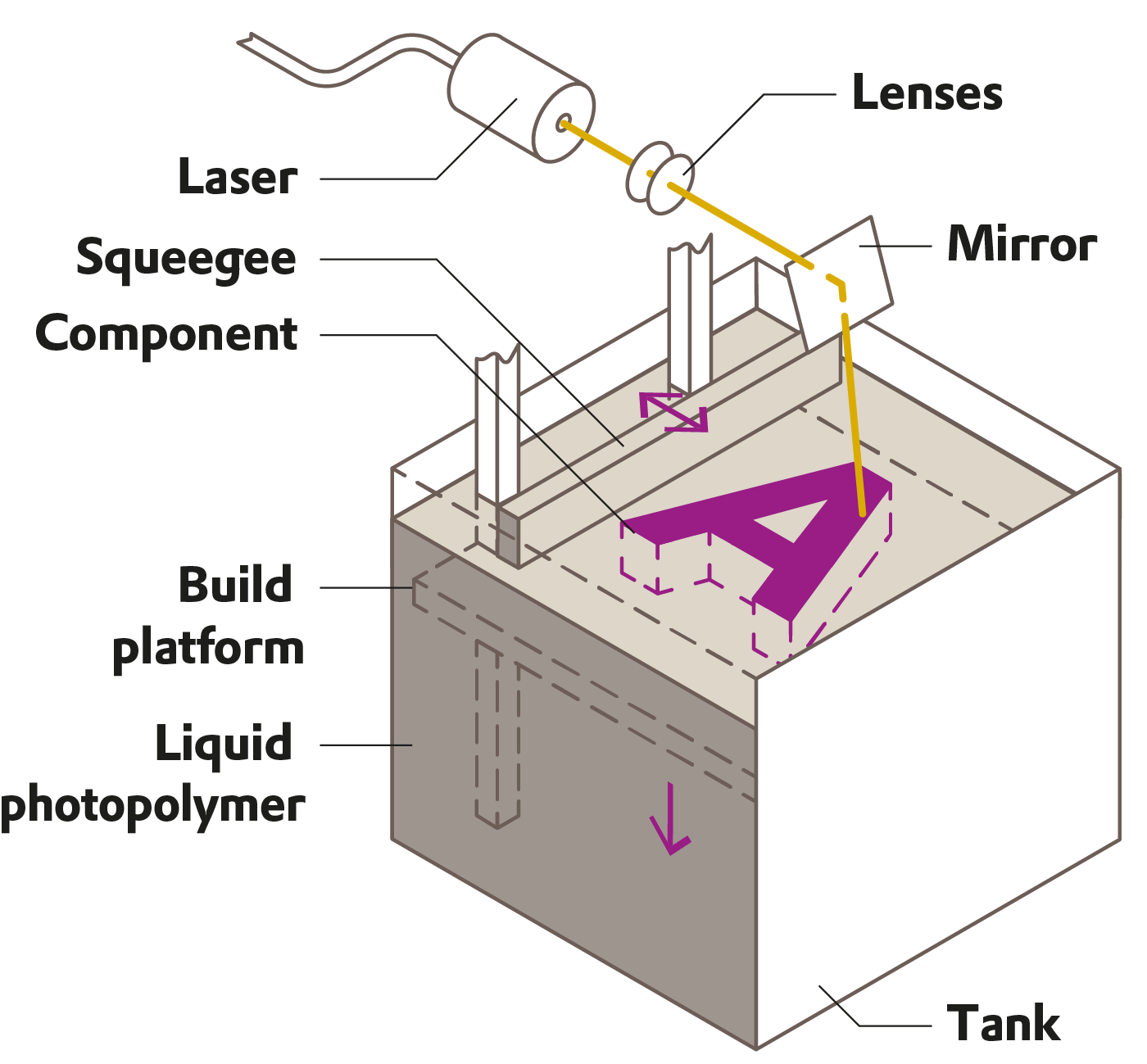

A Tough Material

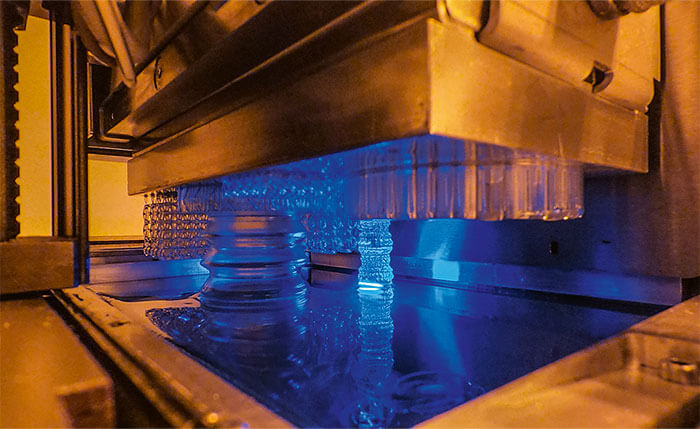

Just one year after Cubicure was founded, the company held its first talks with Creavis, the innovation unit of Evonik, in 2016. Although the young company, which is a spinoff of TU Wien—formally Vienna University of Technology—has extensive experience with promising 3D printing methods, this field still presents it with numerous challenges. Stereolithography (SLA) creates components out of a liquid resin that reacts with light. The process is extremely precise, ”but conventional resins are brittle and most of the finished parts have a lot of warping,” says CEO Robert Gmeiner. The problem is that SLA techniques use low-viscosity materials. “It would be better to use high-viscosity resins and pastes, but they are still hard to work with,” says Gmeiner. However, the Hot Lithography method developed by Cubicure enables such viscous materials to be processed with the help of a special temperature control system. In order to improve the technology further, Cubicure is cooperating with companies that to date have used injection molding processes. CAT scans show how close the new technology’s results are now to those of the conventional manufacturing process. Evonik and Cubicure have together tested various raw materials. They have found a number of promising candidates among reactive polyesters. “We have since then worked together in order to pave the way for product development,” says Gmeiner.

By Other Means

Castor supports manufacturers that are introducing 3D printing. This Israeli startup has developed a system that analyzes engineering designs using their underlying CAD files and simultaneously evaluates thousands of components. It works out what kind of geometry characteristics each component needs to have, what kinds of processes and materials could be used to print them, and whether 3D printing would pay off. Castor is initially focusing on complex components that are manufactured in small batches. Its customers include several Fortune 500 companies. “We help companies harvest very low-hanging fruit,” says the company’s cofounder and CEO, Omer Blaier. “We also help them to adapt their engineering designs to the 3D printing process.” For example, the Castor system suggests which of the components that are located close together can be printed in 3D as a continuous workpiece. It also recommends service providers that support customers as they convert their production processes to 3D printing. Castor does not create any fundamentally new designs. “That’s still the job of the engineers. We only help them along the way,” Blaier says. He regards Evonik’s entry as a new investor in Castor as a win-win situation: “Evonik receives access to additive manufacturing end users and to the problems they want to solve—and we’re helped by Evonik’s expertise as we improve our software.”

Hot off the Press

It all began with a used digital printer that had been bought discreetly in an auction on eBay and then rebuilt in a garage. The US startup Evolve emerged from a development project of the 3D printing company Stratasys. Today Evolve’s investors include Lego, and Stanley Black & Decker. The company’s technology is based on laser printing. An image is created on a roller by means of an electric charge. Toner sticks to the charged areas, and the image is then transferred onto a high-speed electrostatic belt and transported to a layer bonding mechanism. “We first deposit the image layer by layer,” explains the Vice President of Evolve, Rich Allen. “After that, we compress the structure while applying heat in order to produce a stable part.” The main advantages of this process, which is now in the commercialization phase, are as follows: It’s quick, because a complete layer of material can be deposited in one go instead of point by point. It prints a large variety of engineering-grade materials, because both the laser printing and the layer bonding process can handle a wide variety of materials. It can also print multi-materials within the same layer because it has five individual printing units. “In addition, because the particles are very tiny the image’s resolution is extremely high compared to traditional manufacturing techniques,” says Allen. Evonik has been working on materials for this process together with Evolve since 2019. “We became partners very quickly,” Allen says. “Both Evonik and our company are aware of this technology’s enormous potential for mass production.”

Photos: Christian Lohfink/Upfront, BMW Group (2), Bastian Werner/Upfront (2), Meditool, Cubicure, Castor technologies LTD, Words at Work, Minneapolis, Volkswagen AG, Harald Reusmann, Local Motors by LMI, EOS

Illustrationen: KNSKB+

Additive manufacturing

The printed plant

Good for the environment and for cost-efficiency: Evonik is using plant components created by 3D printers to construct its own facilities.

Plastic

Implants from the 3D printer

Evonik is investing in the Chinese 3D printing specialist Meditool.

Bioprinting

Improving patients’ quality of life

Wai Yee Yeong talks about the potential benefits of bioprinting for medicine.

Additive manufacturing

3D printing: Facts and figures

Overview: global demand, most used materials and key players.