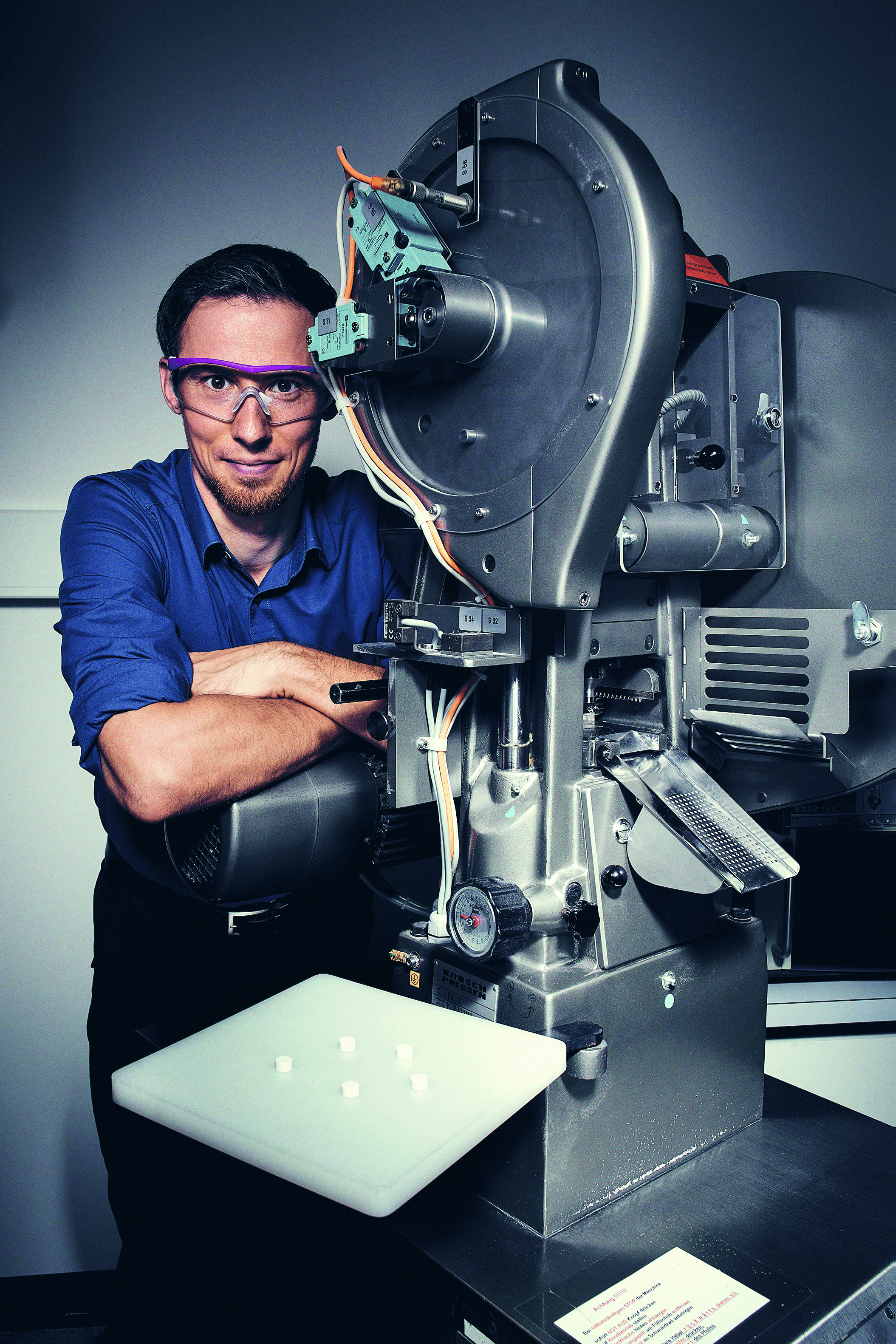

Collagen production

A versatile helper

A biotechnological breakthrough: A new type of platform makes it possible to manufacture different collagens by means of fermentation.

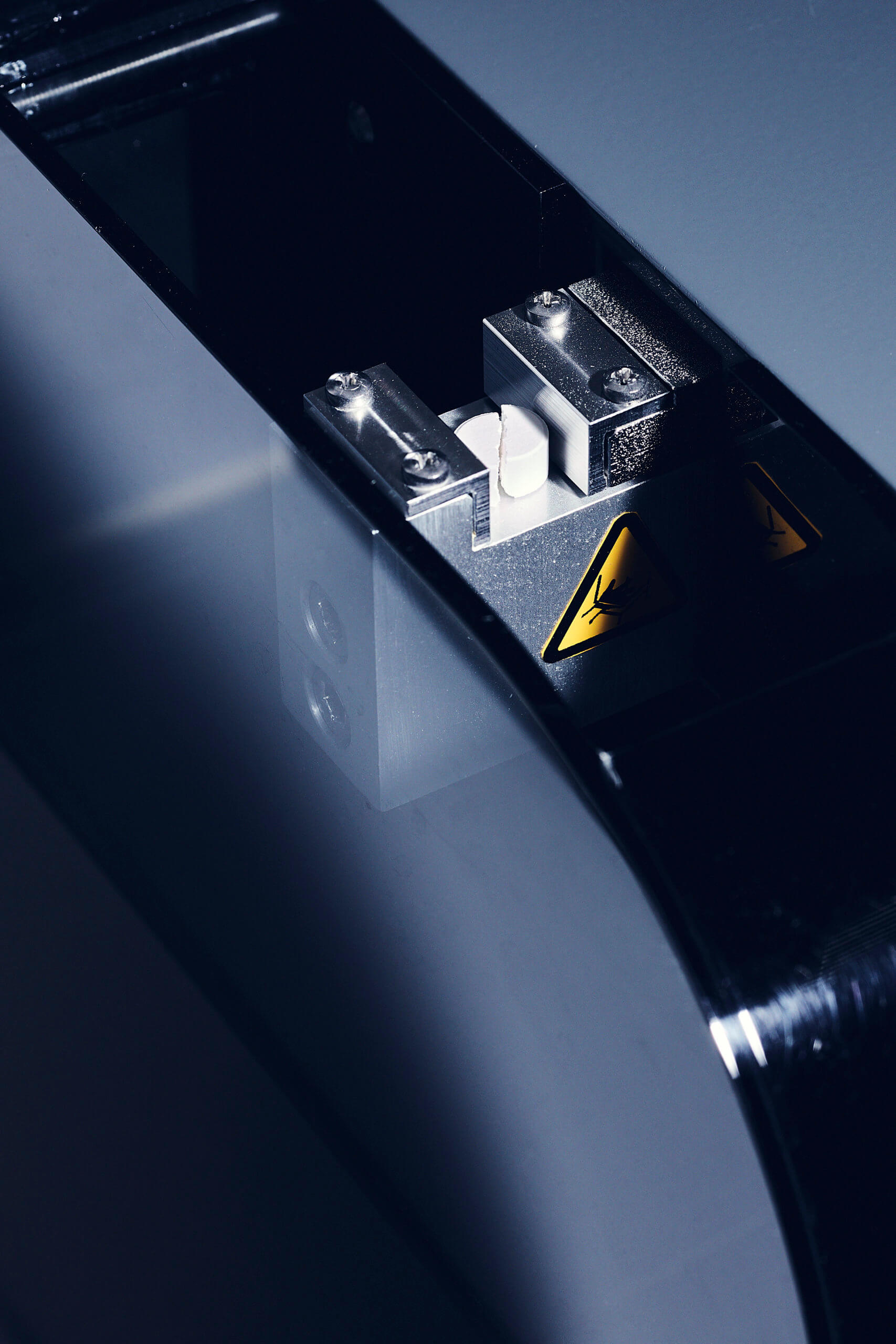

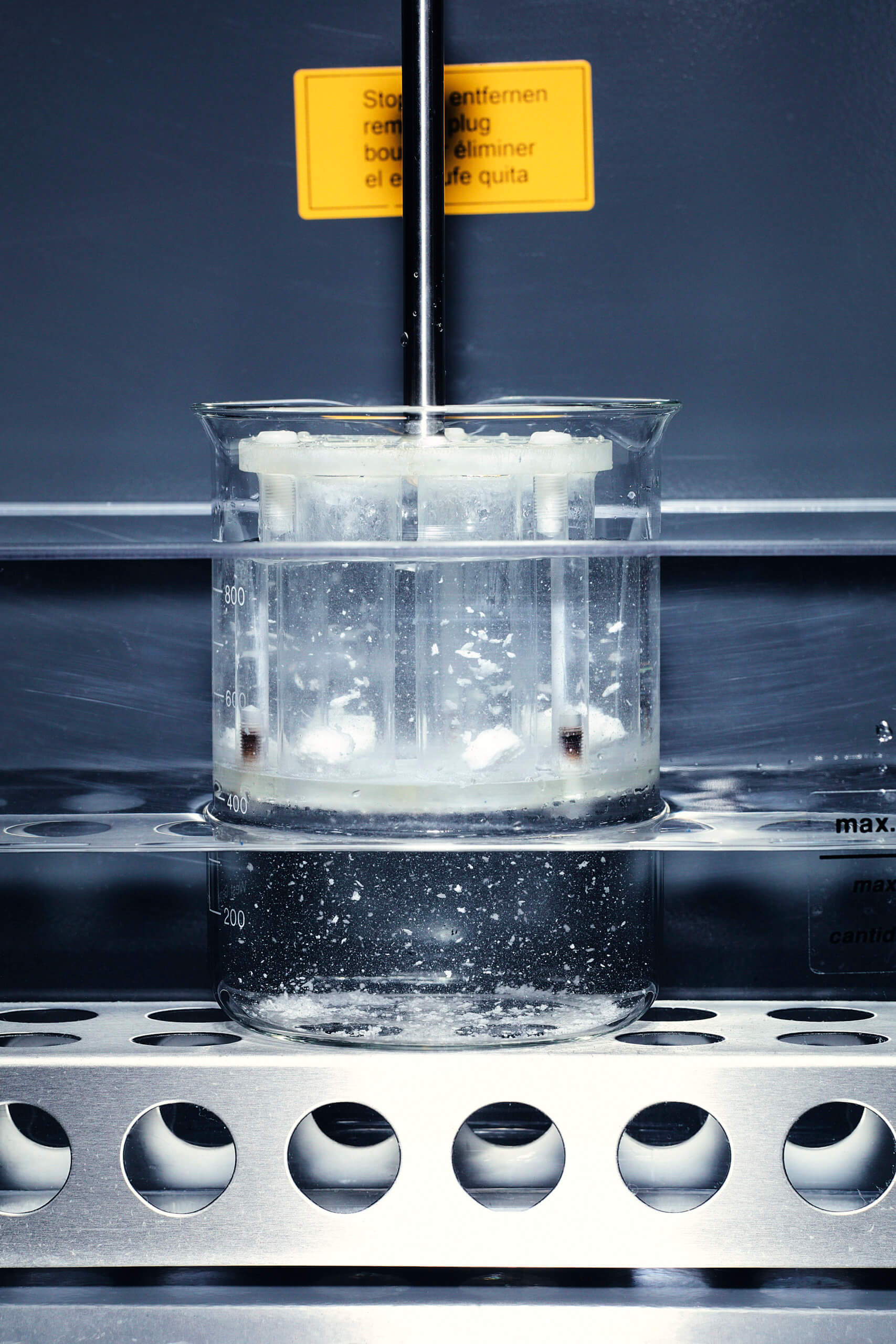

Vaccination

Reliable Transport

Special protection vehicle: Lipid nanoparticles envelop mRNA vaccines and enable their passage through the cell membrane.

Vaccination

Progress thanks to the chemical industry

A marathon, not a sprint: In the interview the virologist Prof. Hengel talks about the challenges involved in developing a new vaccine.

Vaccination

Expensive health?

Nathalie Moll and Dr. Carlos María Correa debate the question of which factors should determine the prices charged for innovative drugs.

ELEMENTS Newsletter

Get fascinating insights into the research Evonik is conducting, and its social relevance, by subscribing to our free newsletter.