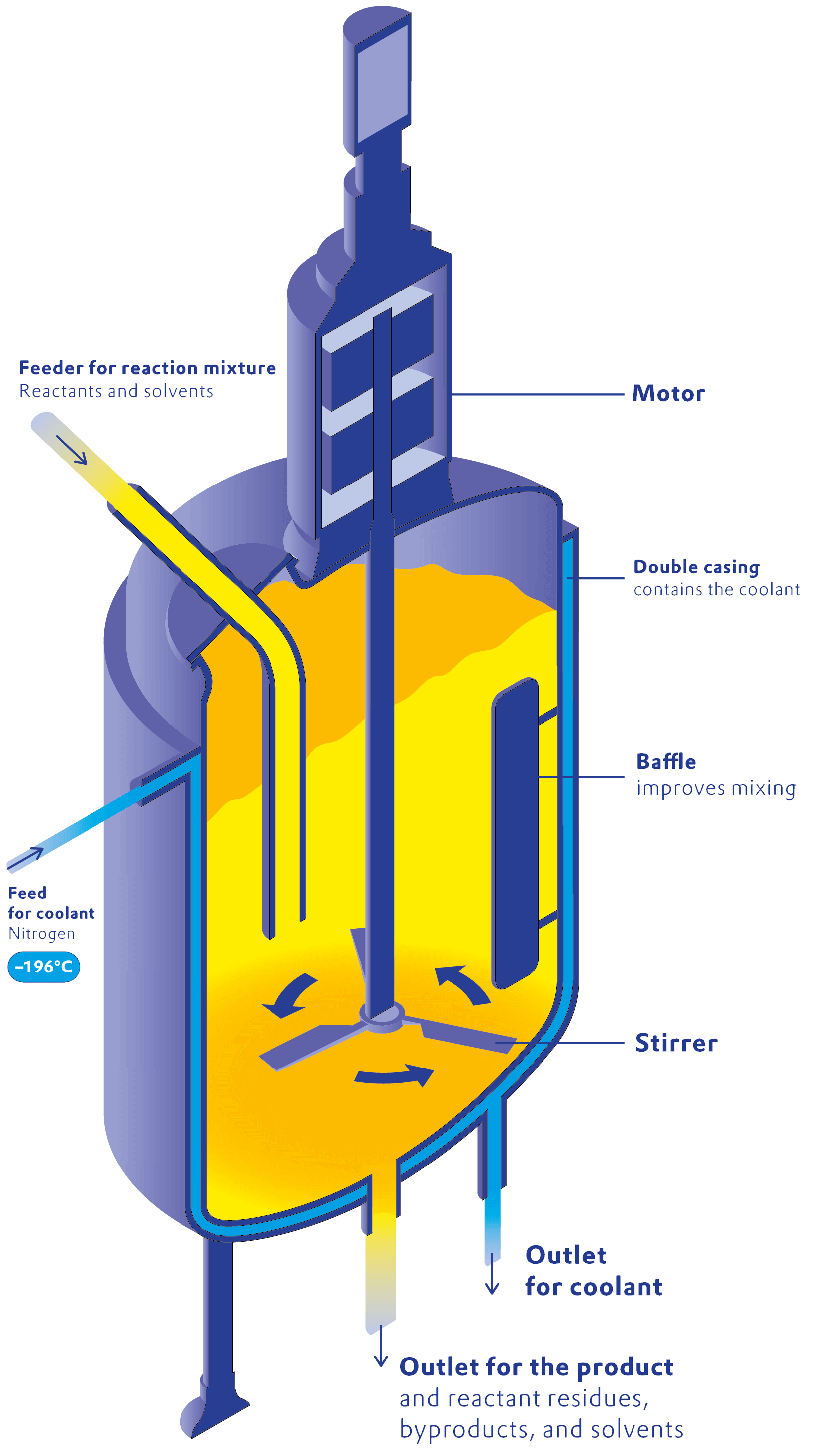

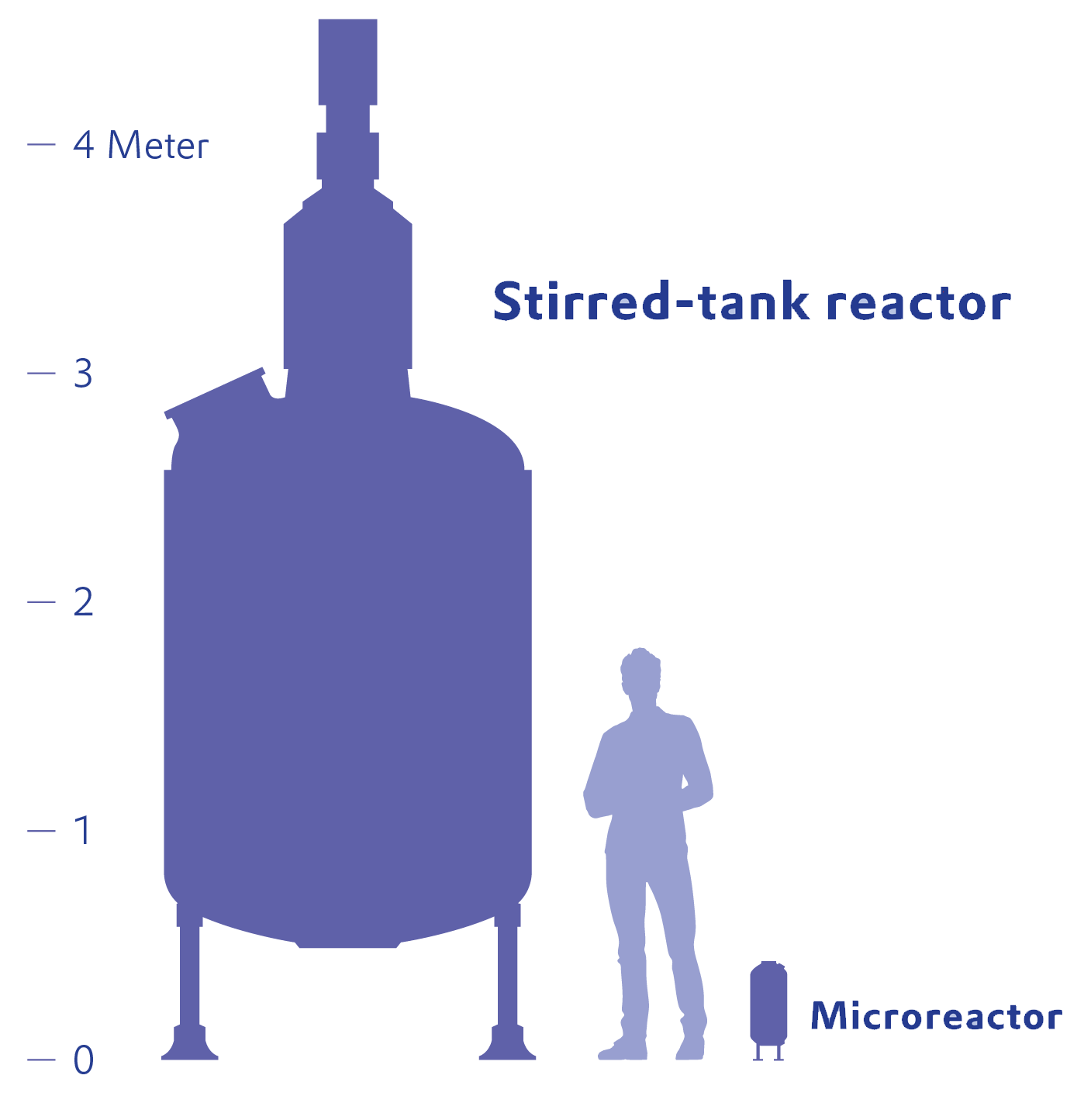

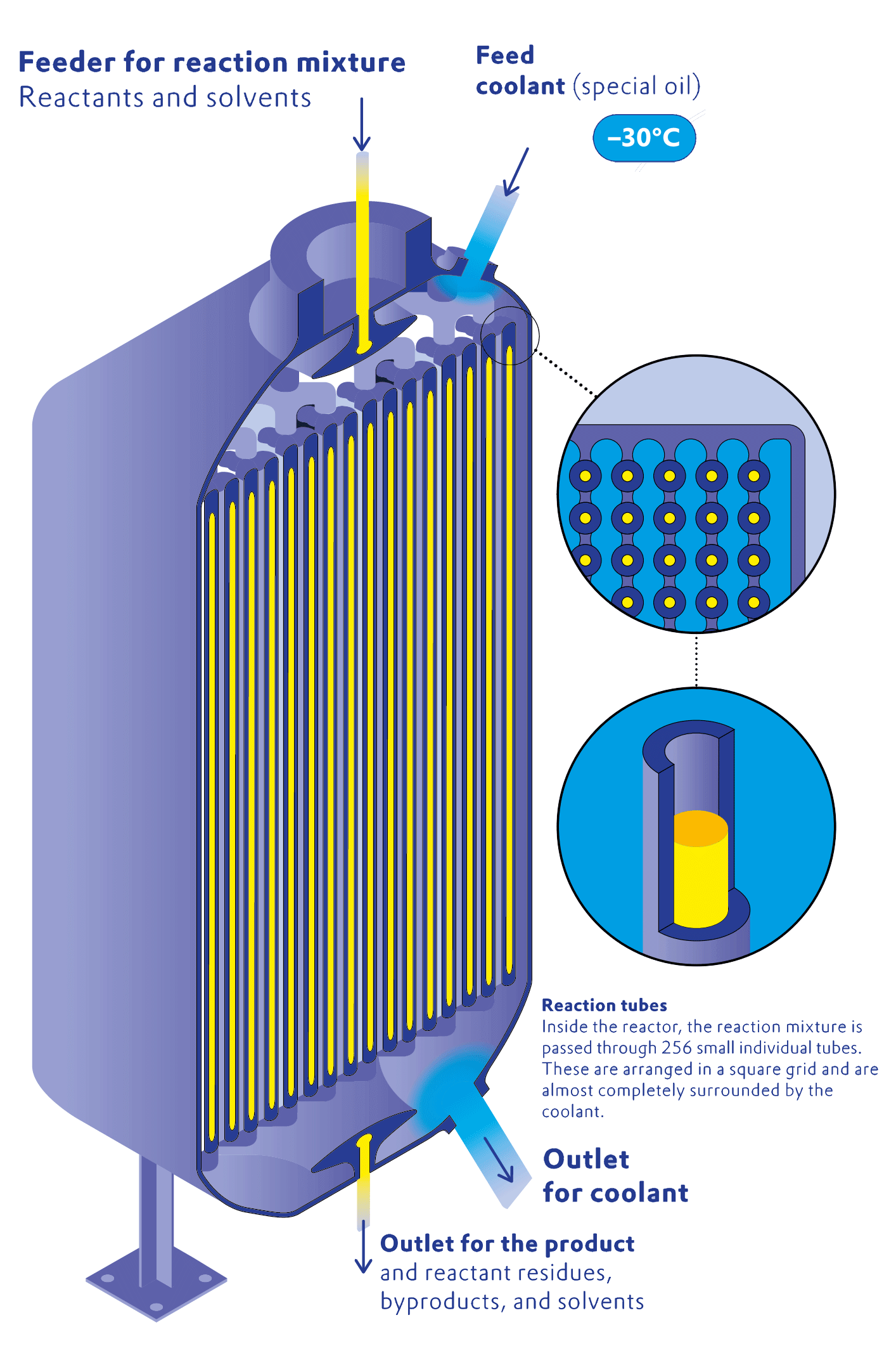

Stirring tank reactor vs. microreactor

When chemicals react with each other, heat is often generated and has to be dissipated. Small flow tanks, which are manufactured using 3D printing, enable more efficient cooling than classic stirred tanks. A comparison of the two systems

publication date3RD AUGUST 2022

INFOGRAPHIC MAXIMILIAN NERTINGER

Stirred-tank reactor

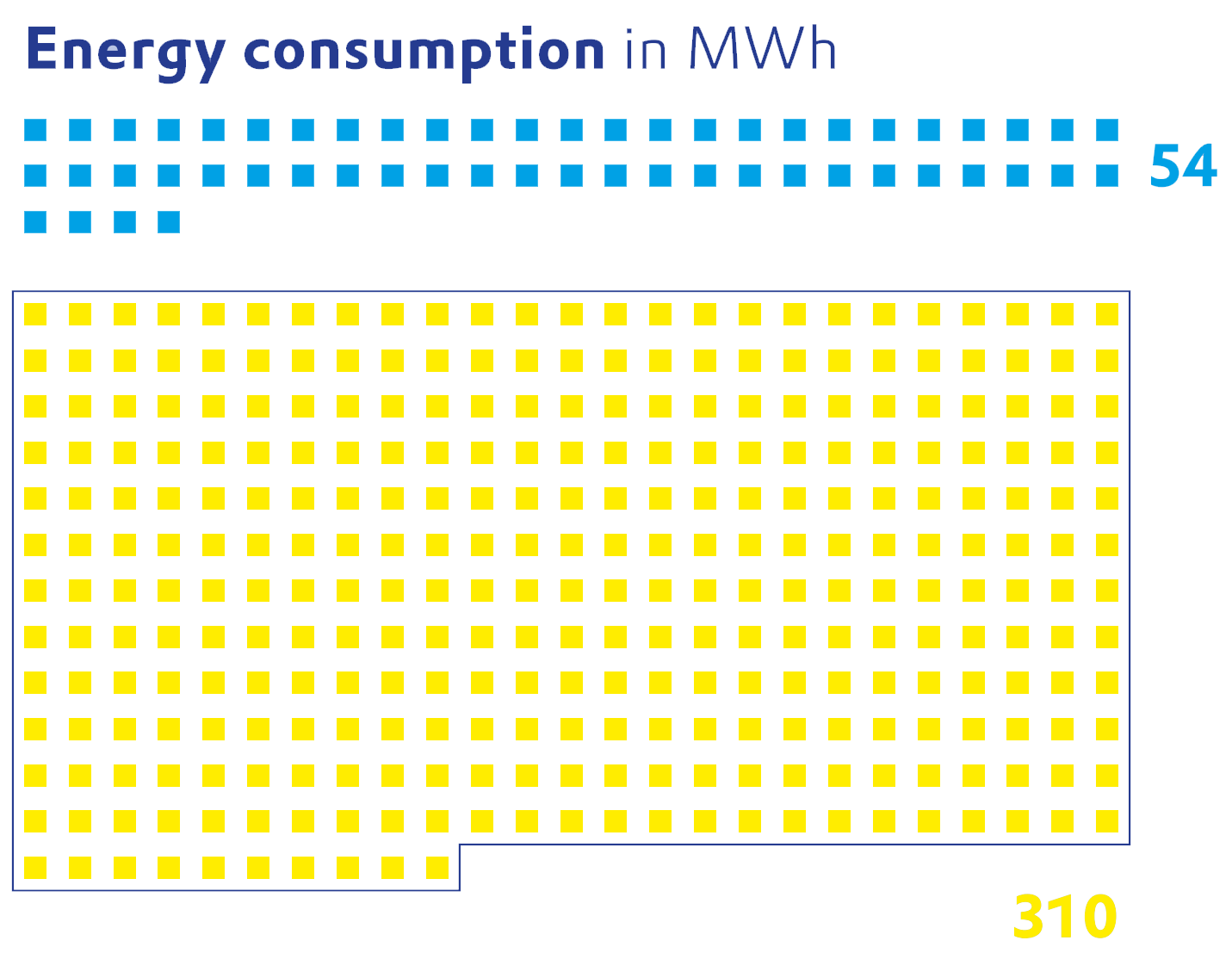

☐ = Ø annual electricity consumption of 100 German households: 310

Source: destatis.de

Stirred-tank reactor

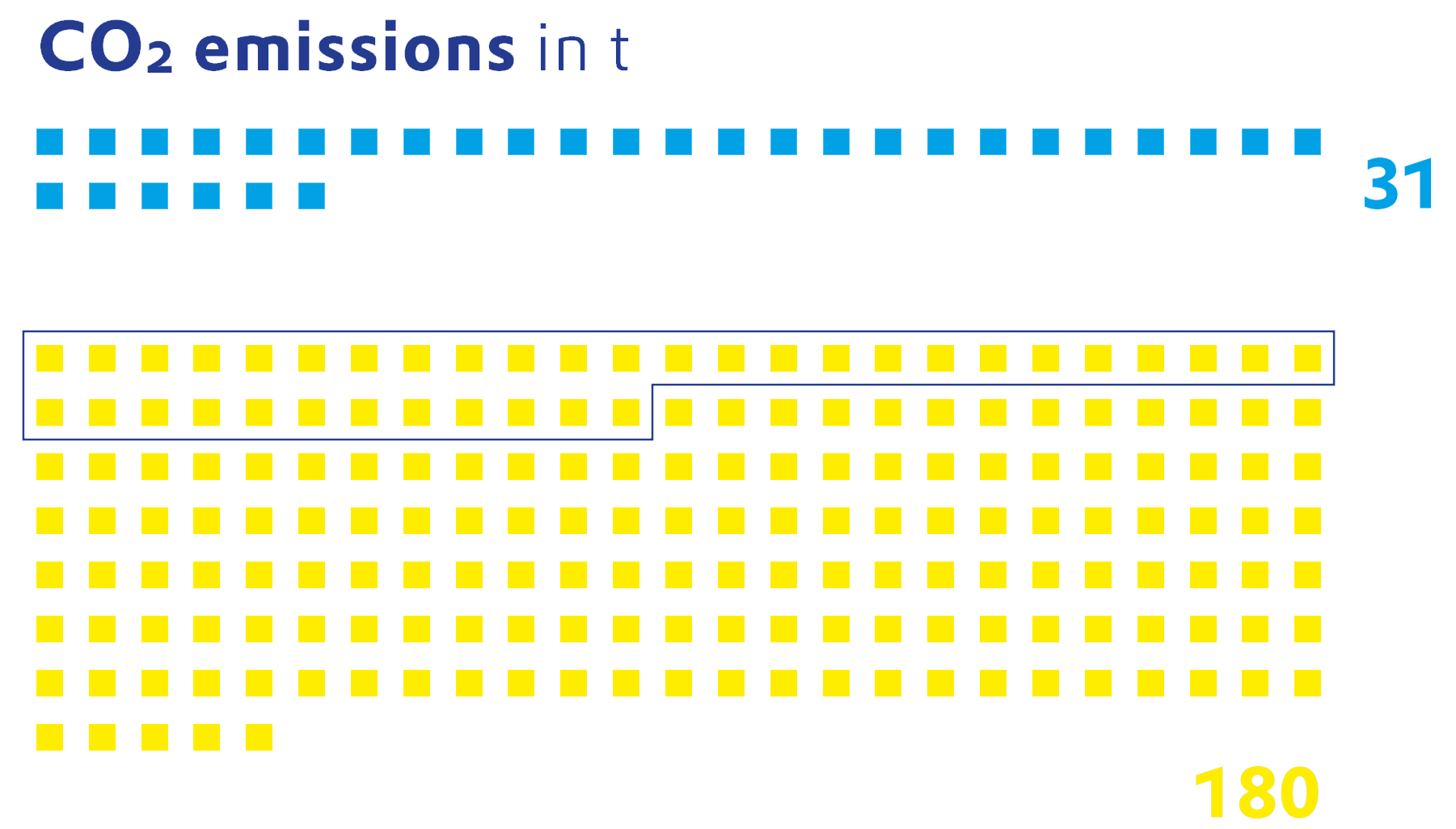

☐ = CO2 emissions of an Airbus A320 on a flight from Munich to Berlin: 37

Source: atmosfair.de

Read more here: Microreactors from the 3D printer

PUBLICATION DATE

2nd August 2022

Efficiency enhancement

Microreactors from the 3D printer

Additive manufacturing opens the door to lower CO2 emissions and less energy consumption in chemical production.

Chemical Production

A reactor with a good energy balance

Researchers in the ROMEO project have developed a process that makes an industrial reaction more energy-efficient.

Climate Change

More efficiency for climate protection

Despite many setbacks, an increase in energy efficiency is still the most viable way to limit the effects of global warming.

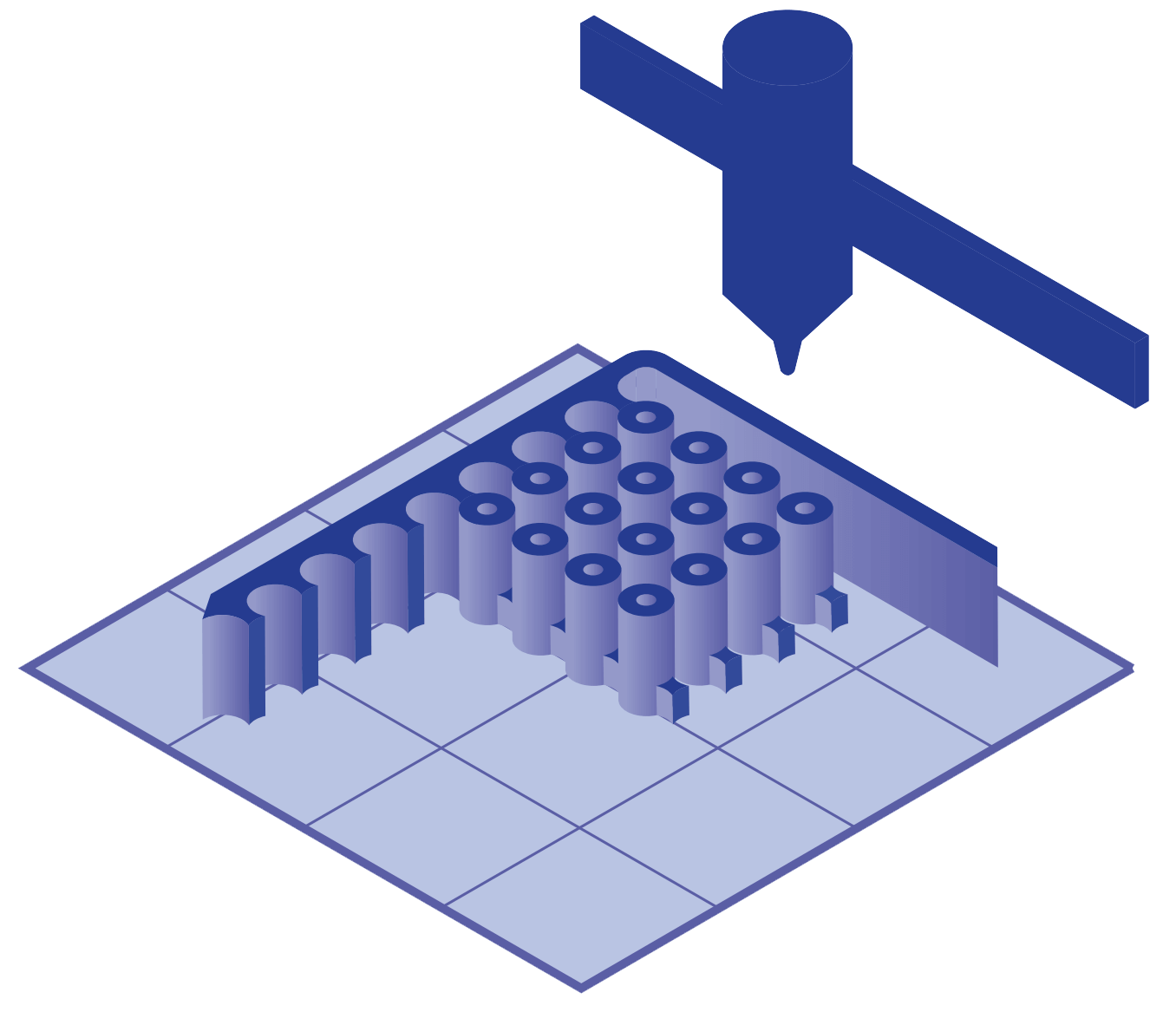

Additive manufacturing

The printed plant

Good for the environment and for cost-efficiency: Evonik is using plant components created by 3D printers to construct its own facilities.