Recycling

The plastic cycle

On the path to achieving a true circular economy: Evonik is working on innovative processes in order to reduce plastic waste.

The circular economy

Closing the circle

Lauren Kjeldsen is promoting circularity at Evonik. The ultimate aim is to create a fully functioning circular economy that works without fossil fuels.

The circular economy

Plastic recycling: Facts and figures

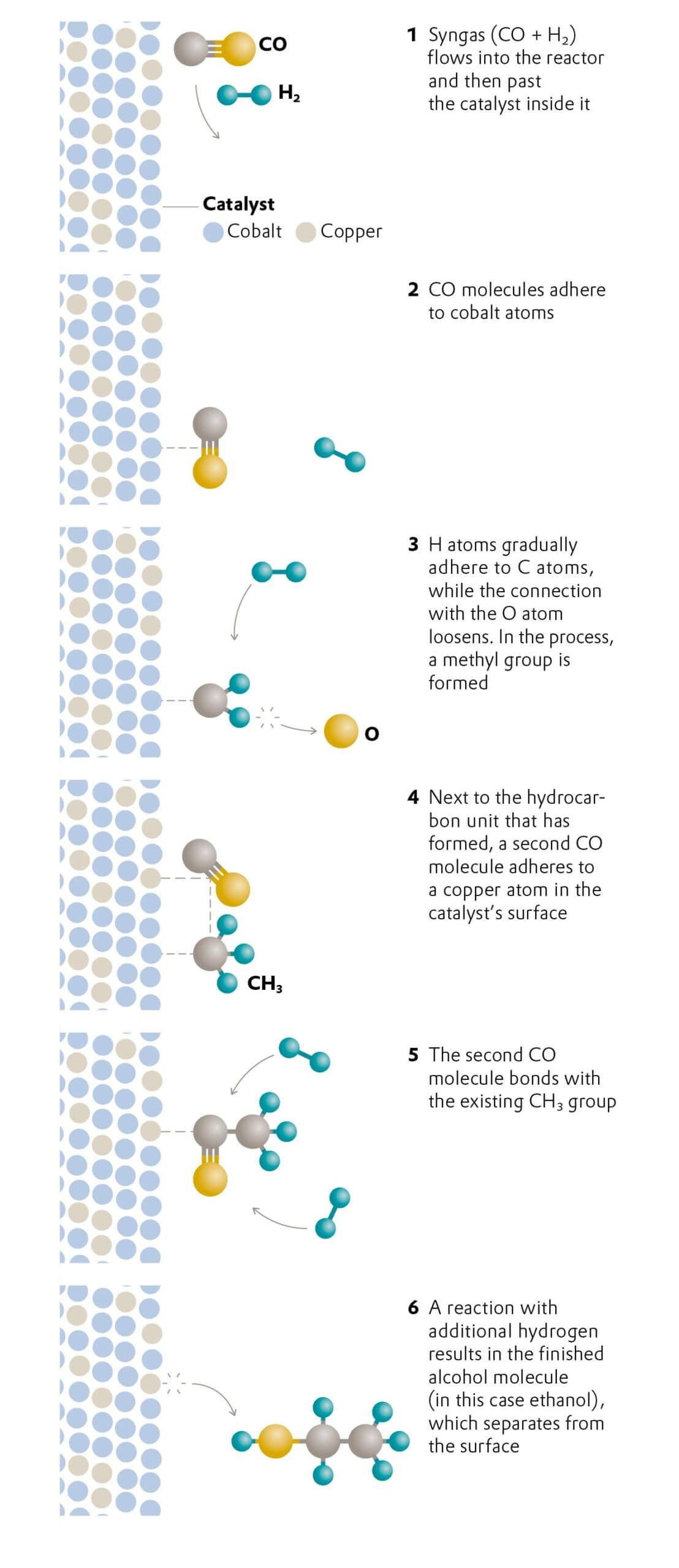

A sustainable cycle: The recycling of plastic requires innovative technologies. An overview.

Plastic

Pathways to the circular economy

Bernhard Bauske and Ingo Sartorius discuss the steps that are needed for the optimal recycling of plastic.

ELEMENTS Newsletter

Get fascinating insights into the research Evonik is conducting, and its social relevance, by subscribing to our free newsletter.