Artificial photosynthesis

How new chemicals are being made from CO₂

Evonik and Siemens produce specialty chemicals from electricity and carbon dioxide with the help of electrolysis and bacteria.

Overview

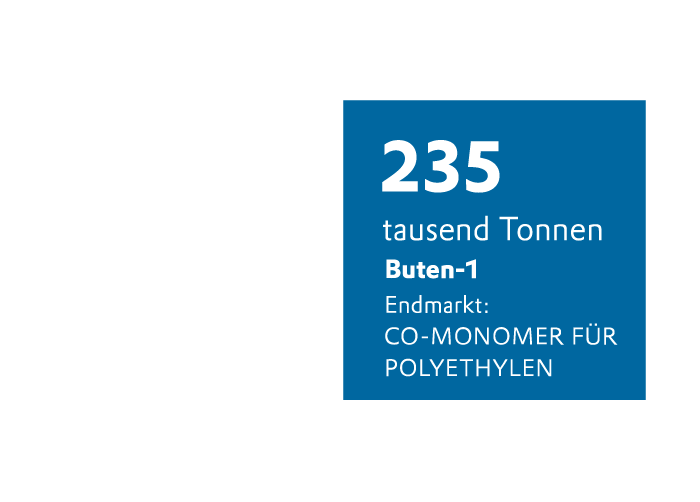

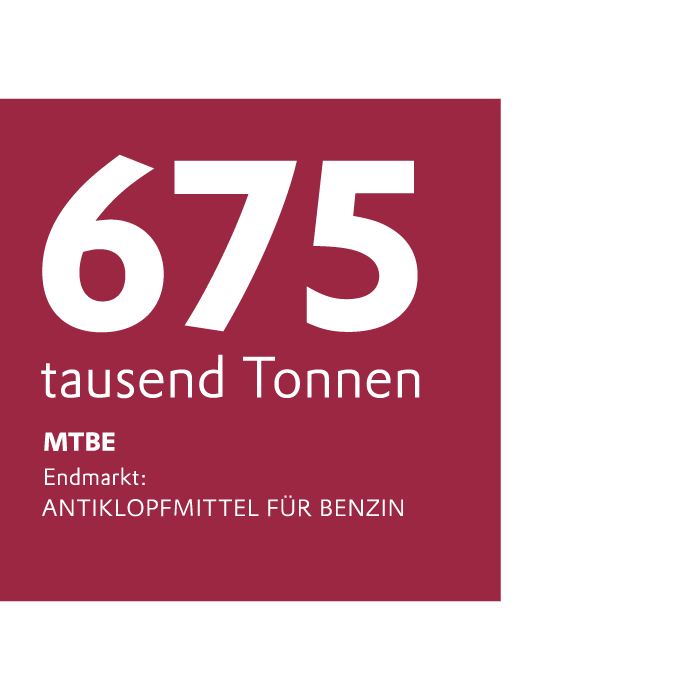

Crude oil: Facts and figures

Facts about the biggest fossil energy carrier: Who extracts how much, and what is made from it?

In my element

"Our molecule will make it in the textbooks"

How chemist Moritz Malischewski discovered a whole new side to carbon.

In my Element

“Gold was created in outer space”

This precious metal lies deep underground, but it originated in the depths of space. How? Professor Stephan Rosswog explains.

ELEMENTS Newsletter

Get fascinating insights into the research Evonik is conducting, and its social relevance, by subscribing to our free newsletter.