It would be an almost normal construction site—if it wasn’t for the TV crew. In the small town of Neubeckum, to the north of Germany’s Ruhr region, the local gas utility company is replacing the old steel pipes of the high-pressure gas supply network. The media interest is focused on the new bright-yellow pipes that are being laid here. It’s a first in Germany—the pipes are made from the high-performance polymer polyamide 12, PA 12 for short. The German technical inspection association TÜV has issued an individual approval especially for this job. The pipes in the gas distribution network are about the thickness of a thigh, and they have to withstand an operating pressure of 16 bar. Expectations are high, and not just on the part of the network operator. That’s because the 300-meter-long stretch of new pipe could signal the sector’s farewell to steel. It would mark a decisive change, and not the first one that PA 12 has triggered.

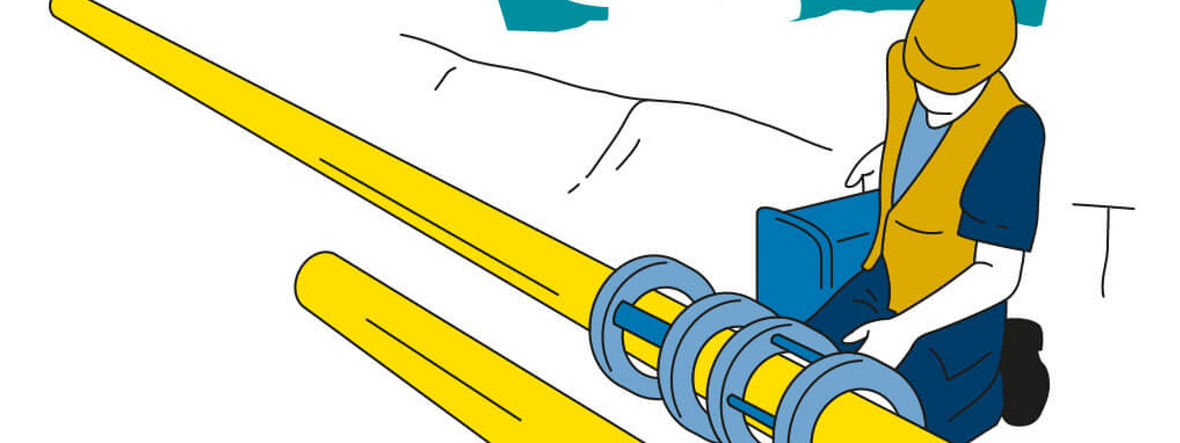

What the TV team doesn’t see, but the construction crew notices immediately, is that the PA 12 pipe is much easier to lay than steel pipe. The individual elements are maneuvered into the roadbed by hand. A couple of electrical heating elements are sufficient to fuse the blunt ends together. Basically, the new pipe could even be laid from a roll. Between 150 and 200 meters fit on a drum, while steel pipe segments that are transported by truck can have a maximum length of 18 meters. Laying pipe from a roll can also be carried out without a trench—through a horizontal borehole. That saves not only welds but also a great deal of digging. PA 12 pipes running for tens of kilometers have already been installed in this way in Brazil. But it’s not only the laying but also the operation of the new plastic pipes that promises to be much easier. Corrosion protection is no longer necessary. And the pipe can even be temporarily squeezed closed when the network has to be extended or serviced.

Polyamid 12: High-performance polymer

Polyamide 12 is a partially crystalline plastic with good dimensional and temperature stability and good damping characteristics for noise and vibrations. It has the lowest density of any polyamide and absorbsthe least water. The suffix “12” refers to the molecular structure of the individual building blocks. They are composed of 12 carbon atoms and are distinguished by a particularly long alkyl chain. This fact, together with the interaction between specific parts of the molecule, make the plastic especially impact-resistant and resistant to oils, fuels, and other chemicals. Polyamide 12 is thus used in an extremely wide range of applications.

Partially crystalline: composed of regularly arranged (crystalline) and irregularly arranged (amorphous) building blocks

The plastic has already long been used in automaking for brake and fuel lines. It’s especially resistant to hydrocarbons such as gasoline, natural gas, and mineral oil. The pipes don’t swell, even after thousands of hours in contact with fuel, and almost nothing is washed out of the material.

“The automakers’ and their suppliers’ requirements are extremely high and rising further,” says Dr. Sandra Reemers. She heads Innovation Management for the High Performance Polymers unit at Evonik. “The automakers are controlling the combustion inside their engines ever more exactly. That means the injection profile is becoming increasingly complex and the injection nozzles ever finer. The smallest amount of material washed out of the polymer could block these nozzles.” Specially modified PA 12 solves this problem.

Hybrid and electric vehicles, in contrast, use high-performance PA 12 lines for the batteries’ cooling circuits. This is an area where PA 12 can utilize its weight advantages in the future. Range is a decisive criterion for electric vehicles, and every gram saved counts. PA 12 is lighter than steel and doesn’t need threads and nuts because connectors can be closed directly in the component using compressed air.

»The automakers’ requirements regarding materials for fuel lines are extremely high«

SANDRA REEMERS

A GROWING GLOBAL MARKET

The global market for polyamide 12 is growing constantly and strongly, most recently by five percent per year. A number of forces are driving this development. In the emerging economies, demand for cars and other high-value consumer goods has been growing for years. PA 12 is in demand in sports equipment and for household appliances—the baskets in dishwashers, for example, are powder-coated with PA 12. That’s what enables them to withstand years of hot water, aggressive dishwasher tabs, and pans and knives thrown in carelessly.

But some of the growth in PA 12 also comes from new markets. The powder variants are used in 3D printing. Growth in this area is in double digits. PA 12 is in demand here because it is ideally suited for use in various printing processes and can produce components that are as delicate as they are durable. Evonik recognized 3D printing long before the current hype and has been patiently acquiring know-how in this area. For example, PA 12 experts from Marl worked together with renowned printer manufacturers such as EOS, 3D Systems, HP, and voxeljet to develop custom powders for their print technologies.

It’s the material’s versatility that drives the rising demand. “PA 12 is outstandingly easy to modify and totally well behaved,” says Reemers. “We can incorporate other monomers by polymerization and intervene directly in the molecular structure. There are very many compounds that work. That means we can control the material properties by using additives.” Evonik has developed an especially large toolkit for this custom work.

BIG DATA AND ARTIFICIAL INTELLIGENCE

In order to identify further areas of application, the researchers from Evonik intend to also use the methods of big data analysis and artificial intelligence to evaluate the immense amount of data that they have collected over decades of research and development work. Evonik is already using artificial intelligence to comb through the patent literature. Similar systems should also soon be searching through the company’s own data on cause-effect relationships between molecular structure and additives, on the hunt for promising combinations. “We want to use computer support to further investigate what our developers can sometimes intuit on the basis of their decades of experience,” says Reemers.

Being on the ball early and working together closely with the users are also essential ingredients in the recipe for success. “At the end of the day, we ‘just’ deliver the polymer, but we have to ensure that it is going to work without problems in our customers’ machines,” says Reemers. That’s why Evonik keeps examples of all common production machines at the technical center in Marl. The Group has to be able to master processes such as coextrusion—the simultaneous extrusion of pipes made up of multiple polymer layers—at the production speeds required.

The Group is the only supplier on the market that is also completely backward-integrated, i.e. it produces all of the precursor products itself at its Marl location. “We can tune the properties of PA 12 both physically by using additives and chemically,” says Reemers. “Starting from the monomer, we have various building blocks and can develop a complete molecular architecture with respect to the degree of branching, chain lengths, end groups, density, and copolymers.” This is one of the main reasons why Evonik has long been able to maintain its position as the world leader in PA 12.

IMPROVED SOLUTIONS ARE BECOMING NEW STANDARDS

As Reemers explains, the Group is frequently already working in standardization groups on the establishment of new technical standards. “When we develop a better solution it eventually becomes the legal minimum requirement—often just because this better solution exists.” For example, the first test rigs for determining the chemical resistance of plastic pipes were developed in Marl. Today’s industrial standards are based on that work. So Evonik is in demand as a consultant not only about what’s going to be possible tomorrow but also about what’s going to be needed. “We talk about the trends of the coming years with shoe and sports equipment manufacturers, and about stricter future regulations with automakers,” says Reemers. “If we didn’t start development until the customer came to us with his problem, it would usually be too late.”

The developers behind PA 12 also want to teach the material new tricks, so that it can enter new markets. “In the area of electronics, for example, plastics that work well with metals are in demand. PA 12 can do that perfectly,” says Reemers. “If we were to modify the polymer with additives so that it could stand up to the waste heat and conduct it out of the component, that would be an attractive market.”

GROWING CAPACITIES

In order to be able to keep up with the increasing demand for PA 12, Evonik has substantially expanded PA-12 production in Marl. In addition, a completely new production line is to be set up at this location in 2019. The facility will go into operation in 2021 and boost the capacities by more than 50 percent in one move. The Group has budgeted around €400 million for the project—Evonik’s biggest investment in Germany. Locations such as Singapore and Thailand were discussed, but the final decision went to Marl. “Nowhere else has such a good supply of all of the precursor products—and nowhere else has a better understanding of the material and the target markets,” says Marcus von Twistern, who heads the project.

Understanding the markets also requires patience. Oil and gas extraction, automaking or power grids—the hurdles for new materials and technologies are often high. Automobile companies have optimized their production processes over 50 or even 100 years. “We talk with end customers such as VW, Opel, and Ford, but also with Petrobras and Shell about where this journey is going,” says Reemers. She and her team are looking ahead to the year 2030 in order to anticipate trends and scenarios in the areas of technology and legislation. The energy sector in particular is anything but fickle. “Oil and gas applications require a 30-year service life in the hardest offshore environments,” says Reemers. The steel pipes being replaced in Neubeckum had been in operation for almost 70 years. If PA 12 is going to take over from steel in the long term in this sector as well, then the bright-yellow replacements will have to last a long time.

GLOSSAR

Compound A plastic in which fillers and/or additives have been admixed in order to make specific changes to its properties is called a compound.

Copolymere Copolymerization enables the properties of a plastic to be influenced by uniting different plastics with different properties in one polymer.

Extrusion/Coextrusion A forming process that is used for thermoplastics, among other materials. Coextrusion is a process in which multiple materials are brought together in the production process