Do you know anyone …anyone who would claim that we have an infinite supply of oil on planet Earth? Probably not. So how is it that the development of modern organic chemistry has been essentially tied to the availability of petroleum and the downstream products? For over 200 years, society’s dependence on these products has been growing. From the pharmaceuticals that keep us alive to the herbicides and pesticides that enable food production that feeds a growing population, they are produced primarily in petroleum-based organic solvents, which must be disposed of properly when they are spent. What exactly does this mean? To the extent that a very healthy percentage of this organic, and therefore carbon, waste is burned, the result is CO2. Yes, CO2, and a lot of it! So, is chemistry a big contributor to climate change? Shhhh… yes!

It’s not that hard to change this. In fact, if “change” is based solely on science, then we are already there, in harmony with biology, which is water-based. And the payoff is substantial, replete with bonuses reflecting much more than minimizing pollution and ensuring that planetary resources are available to future generations. Put another way, going green is a win-win on all levels.

SEARCHING FOR THE APPROPRIATE REACTION VESSEL

The secret to doing organic chemistry in water is no secret at all; rather, it has been hidden in plain sight, perhaps for billions of years. Nature itself provides the answer: Life could not exist without the synthesis of complex, water-insoluble biomolecules such as polypeptides or vitamins under aqueous conditions. The power of “chemistry in water” is actually something we experience at first hand every day. On a large scale, “chemistry in water” can also be observed when oil companies clean up marine spills. It’s obvious: The know-how is already there, at least conceptually. So why has organic synthesis been so slow to adapt?

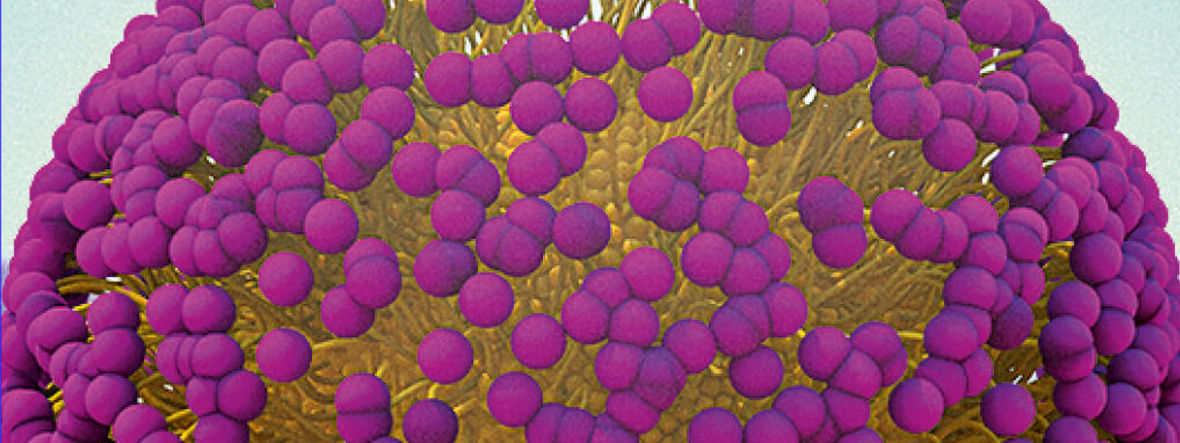

The challenge lies in finding the appropriate “reaction vessels” for water-insoluble biomolecules. Throughout evolution, nature’s reaction “flasks” for water-insoluble biomolecules have been, and still are, a variety of membranes, vesicles, and micellar arrays, in water. Could it be that simple?

Yes and no. The good news is that, in principle, organic synthesis should be possible in these reactors; the reactants would be accommodated, as well as the catalysts that speed up these reactions. Making all sorts of products would then be feasible because, unlike enzymes, these particular biomolecules are “brain-dead”; they have no biases and no recognition of what’s coming in to react and what products are being formed.

The bad news is that a nanoreactor must be identified that is suitable for organic synthesis; it must be capable of accommodating many different types of chemistry, such as that routinely used by the fine chemical industry (especially pharmaceutical and agrochemical companies). This has been the “valley of death” that has remained unfilled for centuries: It is the difference between recognizing the need and creating the technologies that make organic synthesis “in water” possible. Let’s understand that it’s the nanoreactors that are “in water”; the actual chemistry involving water-insoluble reactants and catalysts takes place within the inner cores, which serve as the “solvent” for various reactions.

Nature, with its membranes, vesicles and micelles, has likely relied on these concepts over the millennia for its chemistry in water involving insoluble educts. Molecules of interest within the fine chemicals industry tend to be rather complex, so the tools needed to make them in water need to be equally sophisticated. Therefore, new surfactants to be used in an aqueous medium, present in very limited amounts, must not only be “benign by design” but must also allow many reactions to be run efficiently. Did someone just ask, “What about palladium chemistry?”

To apply such guidelines to modern synthesis, and especially to transition metal-catalyzed reactions, these processes must subscribe to many of the twelve Principles of Green Chemistry. Does the literature on micellar catalysis provide any hints, background, or precedent to help organic chemistry make the switch to water? Unfortunately, no, no, and no.

That’s not to say that there isn’t considerable prior knowledge about micellar catalysis; there is. But its use by the fine chemicals industry has been, at best, hit or miss. Over the past 15 years, however, a lot of trial and error has led to a much better understanding of surfactant design, leading to micellar catalysis which today is becoming rich with a growing toolbox of technologies that enable just about any reaction to be run in water.

The leading “designer” surfactant to date is TPGS-750-M, which contains the MPEG-750-containing hydrophilic group. It is divided into three parts. The hydrophilic section facing outward in water contains the building block methoxy polyethylene glycol 750 (MPEG 750). The inner, or lipophilic, portion consists of the commodity chemical vitamin E. The two building blocks are connected by a succinic acid linker. Each portion of this designer surfactant is innocuous and, due to the vitamin E present, even by itself, healthy!

»Micellar catalysis is becoming rich with a growing toolbox of technologies that enable just about any reaction to be run in water«

Bruce Lipshutz Pioneer of green chemistry

ENVIRONMENTAL AND ECONOMIC BENEFITS

This micelle-forming amphiphile, TPGS-750-M, can be used to affect many different reaction types, especially those of particular interest to pharmaceutical and agrochemical companies. Key reactions, including those catalyzed by palladium, amide/peptide bond formations, and Nucleophilic Aromatic Substitution reaction (SNAr) processes that have traditionally been run in organic solvents can be accommodated.

In addition to the environmental and associated economic benefits to be realized, the higher concentrations of substrates and catalyst localized within the inner micellar cores not only lead to faster reactions but also provide opportunities to use precious metal catalysis at ppm loadings.

Since most targets are water-insoluble solids, they precipitate from the aqueous medium and need only be filtered for isolation purposes. How’s that for a “work-up”? And what about the filtrate, the aqueous medium that often contains the catalyst? It’s recycled. Boom!

Do we really have a choice? If we already have the know-how to stretch our limited planetary resources, what’s the downside to doing more with less? Perhaps the bigger question is: Do we have the resolve in the chemical industry to make these changes? Let’s hope so. Sustainability is not just a buzzword; it has tremendous implications. Indeed, it is our future.