The new head of process development in Blair, Nebraska, had an ambitious goal. “We can boost the plant’s productivity by 50 percent,” said Dr. Henning Kaemmerer in the fall of 2018, shortly after he had moved to the USA from Hanau. The plant, which had been producing the amino acid BIOLYS® for almost two decades, had been repeatedly optimized after its initial commissioning. But…50 percent? A productivity boost of this magnitude was hard to imagine.

BIOLYS® is added to animal feed—primarily feed for pigs. The animals need L-lysine, an important component of proteins. However, like human beings, they cannot produce this amino acid on their own, so they have to take it in with their feed. The amounts of the amino acid L-lysine in the plant-based components of pig feed are very low. If BIOLYS® is added to the feed as a source of lysine, the volume of the feed can be significantly reduced. That relieves the animals’ metabolic processes, conserves natural resources, and reduces feed costs and emissions.

FRUGAL PRODUCERS

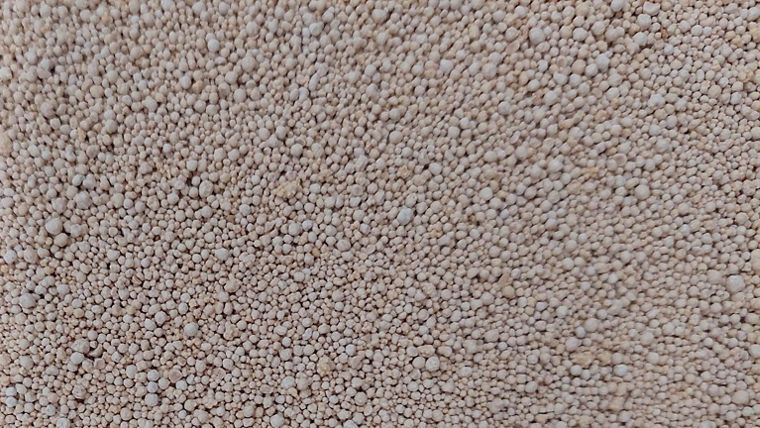

BIOLYS® is produced by means of fermentation. In gigantic stainless steel boilers, each with a volume of several hundred cubic meters, bacteria convert dextrose, a sugar, into L-lysine—much more of it than they need for themselves. The BIOLYS® process at Evonik uses a strain of Corynebacterium. The process engineers provide the ideal conditions for its growth and production processes: an aqueous medium, the right temperature, a plentiful supply of oxygen, and some mineral substances. After several days in the fermenter, the organisms are inactivated and the fermentation broth is drawn off and then vaporized. The mixture of lysine and bacterial biomass is the basis of the product, which is subsequently processed into a granular form that is easy to handle as animal feed.

Far more than 20 generations of this bacterial strain have been used since 2000. Each strain was a bit more frugal than its predecessor; in other words, it converted more sugar into lysine. But a real production boost resulted from an innovation that was promoted by the ambitious engineer Henning Kaemmerer. Within a few months, the Evonik engineers in Blair succeeded in switching the BIOLYS® process to “semi-continuous” operation. Several times during the cultivation phase, part of the fermentation broth was removed and replaced with water, sugar, and the other ingredients. As a result, the product volume per fermentation could immediately be substantially increased—as predicted. The promised 50 percent increase was reached in 2019.

INTERNATIONAL KNOWLEDGE TRANSFER

Kaemmerer feels that his approach has been validated. “This shows what is possible when experts from the areas of research, process development, and production cooperate closely and pool their decades of experience regarding the microorganisms and the processes,” he says. That’s because the bacterial strain and the process must be repeatedly adapted to each other. The only unchanging element is the plant itself. As Kaemmerer explains, “The plant defines the limits within which we work.” This has enabled the product quantity per fermenter to be more than tripled since 2000. Simultaneously, the amino acid content of the initial product has increased significantly from BIOLYS®55 to BIOLYS®77.

Other Evonik locations are making good use of the experiences of their colleagues in the USA. “Of course we’ve benefited from the know-how in Blair,” says Miguel Menezes, who is responsible for BIOLYS® production in Castro, Brazil. The plant in Castro was commissioned in 2015.

Since that time, the engineers in Castro have also been tinkering with improvements. Among other things, they have focused on making the production process more sustainable. They have continuously reduced not only the relatively high water requirement of the gigantic fermenters but also the consumption of steam and electricity. Energy is needed to cool the fermenters, operate the stirrers that ensure optimally uniform conditions inside the fermenters, and evaporate the water at the end of the process.

Castro is committed to renewable resources. Hydropower covers a large proportion of the plant’s energy needs, all of the necessary steam is produced with the help of eucalyptus woodchips, and the raw material dextrose is provided by a nearby corn mill. The plant is located in the midst of a corn-producing region that has been used for agriculture for more than 20 years.

Three quarters of the total production is sold in regional markets. That also reduces transportation routes and improves the carbon footprint. A recently conducted life cycle assessment confirms that only 0.1 kilogram of CO2 equivalent is generated per kilogram of BIOLYS®77. Miguel Menezes is proud of this achievement, and Henning Kaemmerer is equally proud of his productivity increase. “We’re very close to achieving a completely climate-neutral production process,” he says. “In that case, the plant in Castro would be Evonik’s first industrial-scale production plant with a neutral carbon footprint.”