Martin Heining still remembers that moment vividly. Five years ago, he discovered a package of salmon fillet in the freezer of a supermarket. He fished it out, held it up proudly, and took a selfie. “When I was finally able to buy salmon that had been fed with our Veramaris algae oil, it was something special,” says the process engineer from Hanau, who has been involved in the development of the algae oil from the very beginning. “I just had to capture that moment.”

The demand for salmon products is rising worldwide. Not only because the fish tastes good to many people, but also because it contains valuable omega-3 fatty acids, eicosapentaenoic acid and docosahexaenoic acid (EPA and DHA). Aquaculture operators supply their salmon with EPA and DHA through feed that contains fish oil from wild catch.

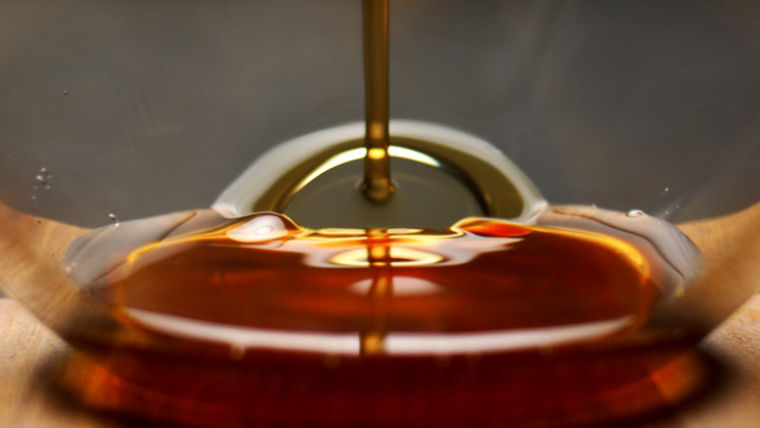

However, the yield from this source can no longer be increased, as marine resources are limited. Veramaris helps meet the demand for omega-3 fatty acids in a different way. The joint venture between Evonik and dsm-firmenich (DSM) produces an algae oil from a special microalgae that is particularly rich in the omega-3 fatty acids EPA and DHA. One ton of Veramaris algae oil provides as much EPA and DHA as 60 tons of feed fish.

Milestones of Veramaris

2011 - Acquisition of Martek

DSM acquires Martek. The U.S. startup had discovered an algae that produces EPA and DHA.

2017 - Establishment of Veramaris

The joint venture Veramaris is founded, with Evonik and DSM each holding a 50 percent stake.

2019 - Start of Production

Veramaris begins operations at its production facility for algae oil in Blair, Nebraska, USA.

2022 - Reduction of Emissions

Veramaris commits to reducing its greenhouse gas emissions. The targets are validated by the Science Based Targets Initiative and align with the Paris Climate Agreement.

2023 - Full Capacity Production

The production facility in Blair operates at full capacity for the first time.

Perfect Partnership

In this regard, Veramaris is far ahead of the competition. In addition to the high content of EPA and DHA, customers appreciate that they don't need to modify their production facilities when switching to the algae oil—the product can be integrated into existing feed formulations just like fish oil. Another advantage is the sustainable production process. Veramaris uses a biotechnological method that results in only one byproduct. "And that is completely fed to cattle," says Heining.

The business with sustainable algae oil is booming. However, Veramaris's order books weren't always as full as they are today. With the acquisition of the U.S. startup Martek in 2011, DSM expanded its portfolio to include an algae that produces EPA and DHA.

Evonik joined in 2015. The partners quickly agreed that Evonik's expertise in biotechnology, plant construction, and scaling up, combined with DSM's knowledge in biology and microorganisms, provided the perfect foundation to jointly develop a production process for the anticipated large-volume market in a joint venture.

The Evonik site in Blair, Nebraska, was chosen for production. "Blair is located in the Midwest of the USA," says Xavier Hakkaart, a bioprocess engineer at the RD&I Biotechnology Hub in Halle-Künsebeck. "While it's far from aquaculture farms, it's close to the raw material corn, which we need to provide sugar for fermentation." Additionally, the site has decades of experience in large-scale biotechnology, expertise from which Veramaris could immediately benefit.

Stay Resilient

Initially, the team faced several challenges. There were technical hurdles in the fermentation facility, and the demand for the new Omega-3 product was still modest. The decision was made to suspend production for six months and sell off existing inventory during that time. The Veramaris team used this period to overcome the obstacles. Under high pressure, the production staff worked on improving the processes. Meanwhile, the marketing and sales colleagues intensified efforts to acquire new customers and formed strategic partnerships with major salmon producers. "Our efforts ultimately paid off," says Heining. "Even before the six months were up, our algae oil facility was back in operation."

ELEMENTS-Newsletter

Receive exciting insights into Evonik's research and its societal relevance—conveniently delivered to your email.

PUSHING BOUNDARIES

In addition to salmon, shrimp are also being fed with the algae oil—available, for example, on the shelves of the Dutch retail chain Albert Heijn. The demand from feed manufacturers far exceeds production volumes. "The support from our parent companies during tough times has particularly helped us stay on track," says Hakkaart. The intensive research from the early years is paying off today. "We are constantly working on improving the facility to optimize its capacity." In 2023, the team already won the PT Excellence Award. "We have also applied for the Evonik Innovation Award," says Hakkaart. Since the facility has been operating at full capacity since 2023, they are already working on a project to expand it. Hakkaart and Heining jointly emphasize, "Perhaps we can add a new chapter to the success story of Veramaris."