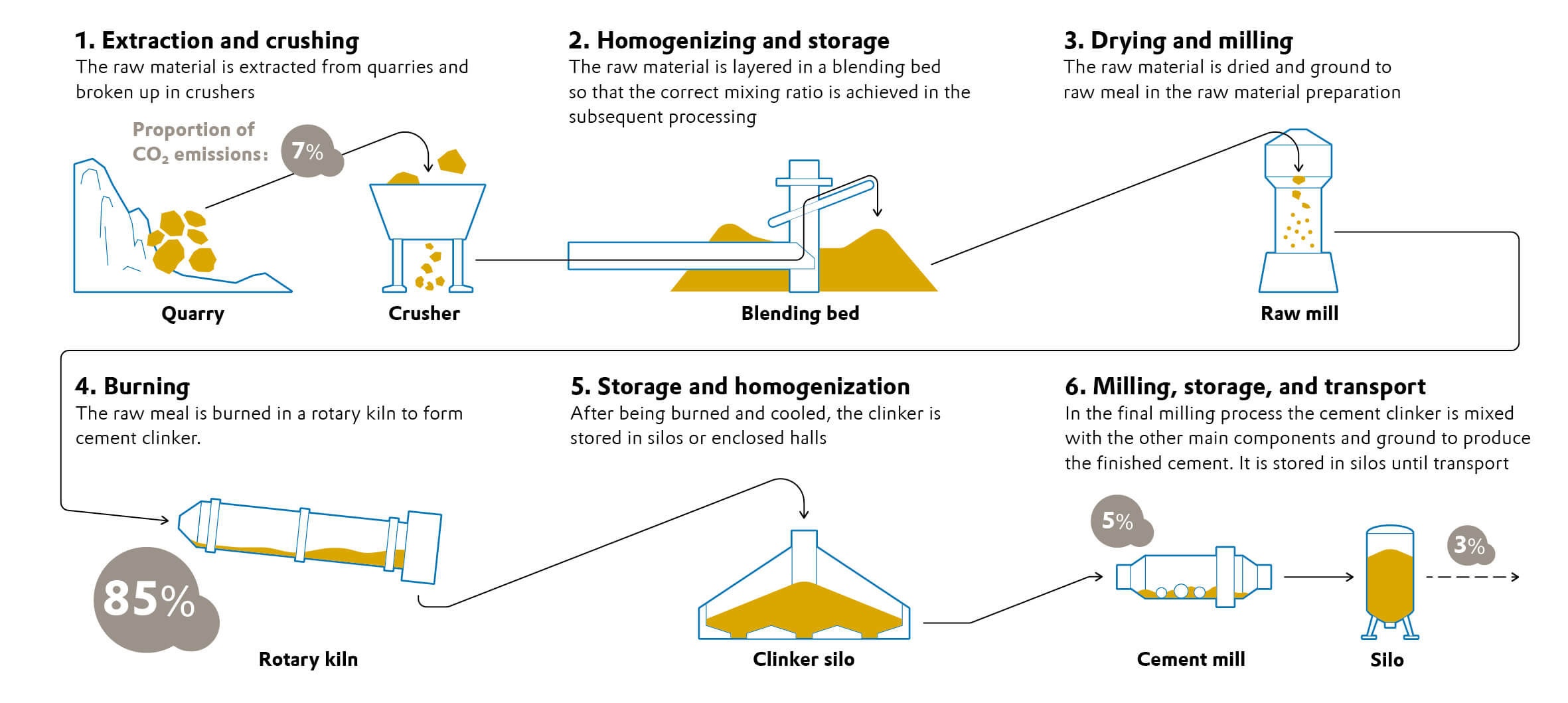

Construction materials

Cement: Facts and figures

Cement is a basic component of concrete that is in demand all over the world. Billions of tons of it are produced annually.

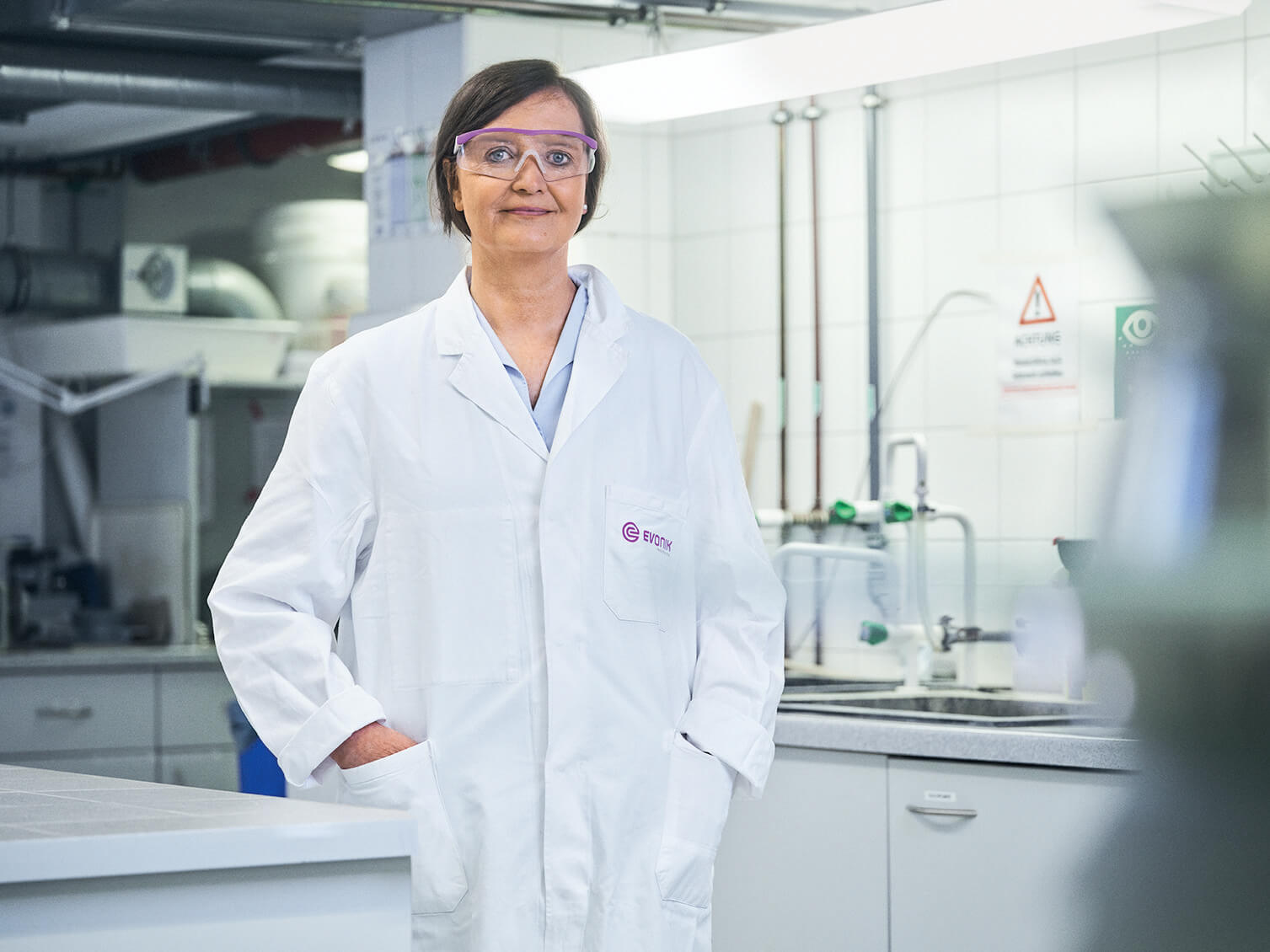

Innovation culture

The driving force

Becoming an entrepreneur during her probation period: Sarah Hintermayer about her role in driving the “WallCraft” project forward.

The recycling economy

Tire test

Vestenamer plays a key role in the manufacture of asphalt from old tires. Now it’s possible to verify the additive’s life cycle assessment with data.

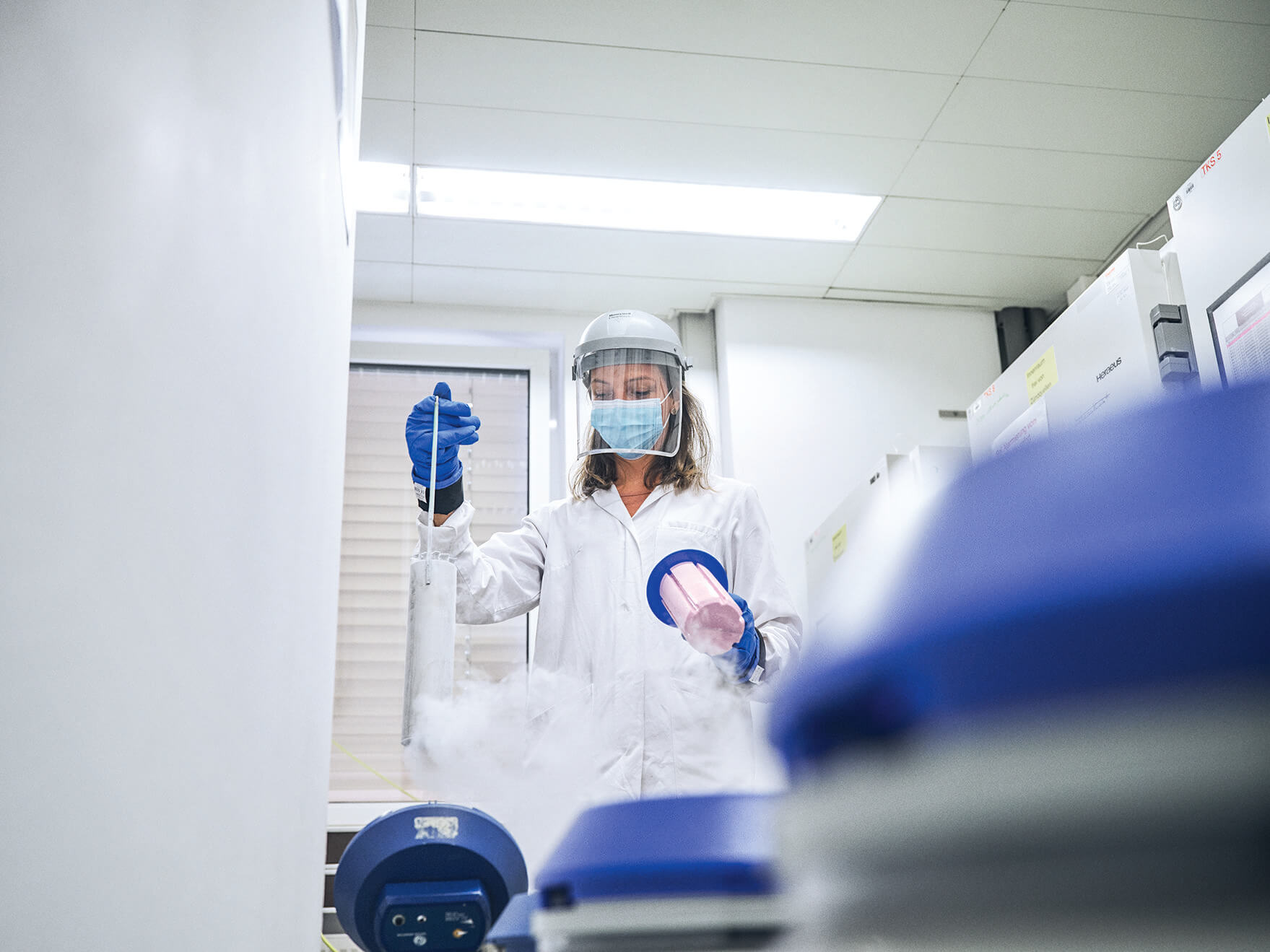

Recycling

Long live plastic

Evonik researchers are working to develop a process for chemical recycling that will make it possible to recycle PET plastic waste.

ELEMENTS Newsletter

Get fascinating insights into the research Evonik is conducting, and its social relevance, by subscribing to our free newsletter.