Biotechnology

The green revolution

Undreamed-of opportunities: Biotechnology has a long history and is one of the key sciences of the 21st century.

Innovation

Growth thanks to biotechnology

Is biotechnology a booster for the economy? Which sectors are benefiting from these innovations? An outlook in figures.

Technology assessment

A joint effort in biotechnology

Martina Schraudner, a specialist in molecular biology and scientific theory, is calling for a public debate about biotechnology.

Vaccination

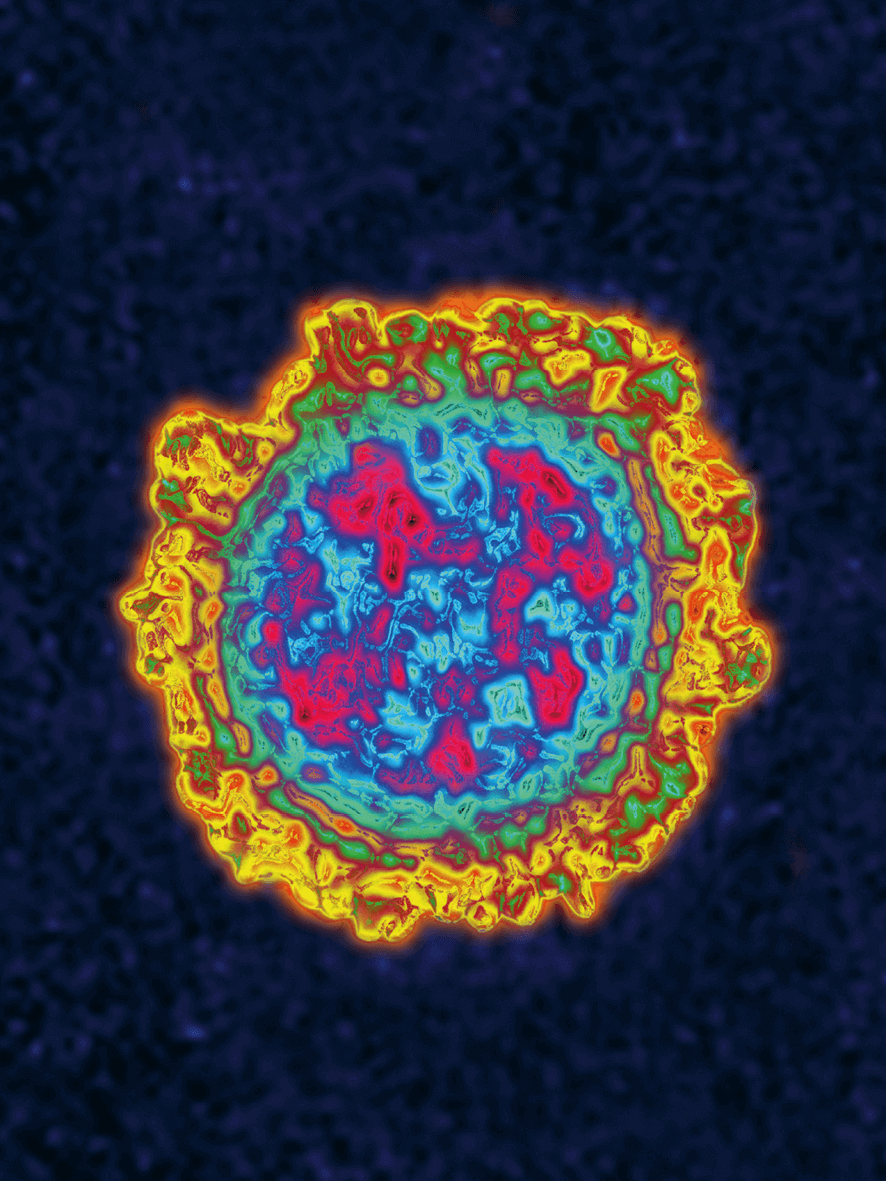

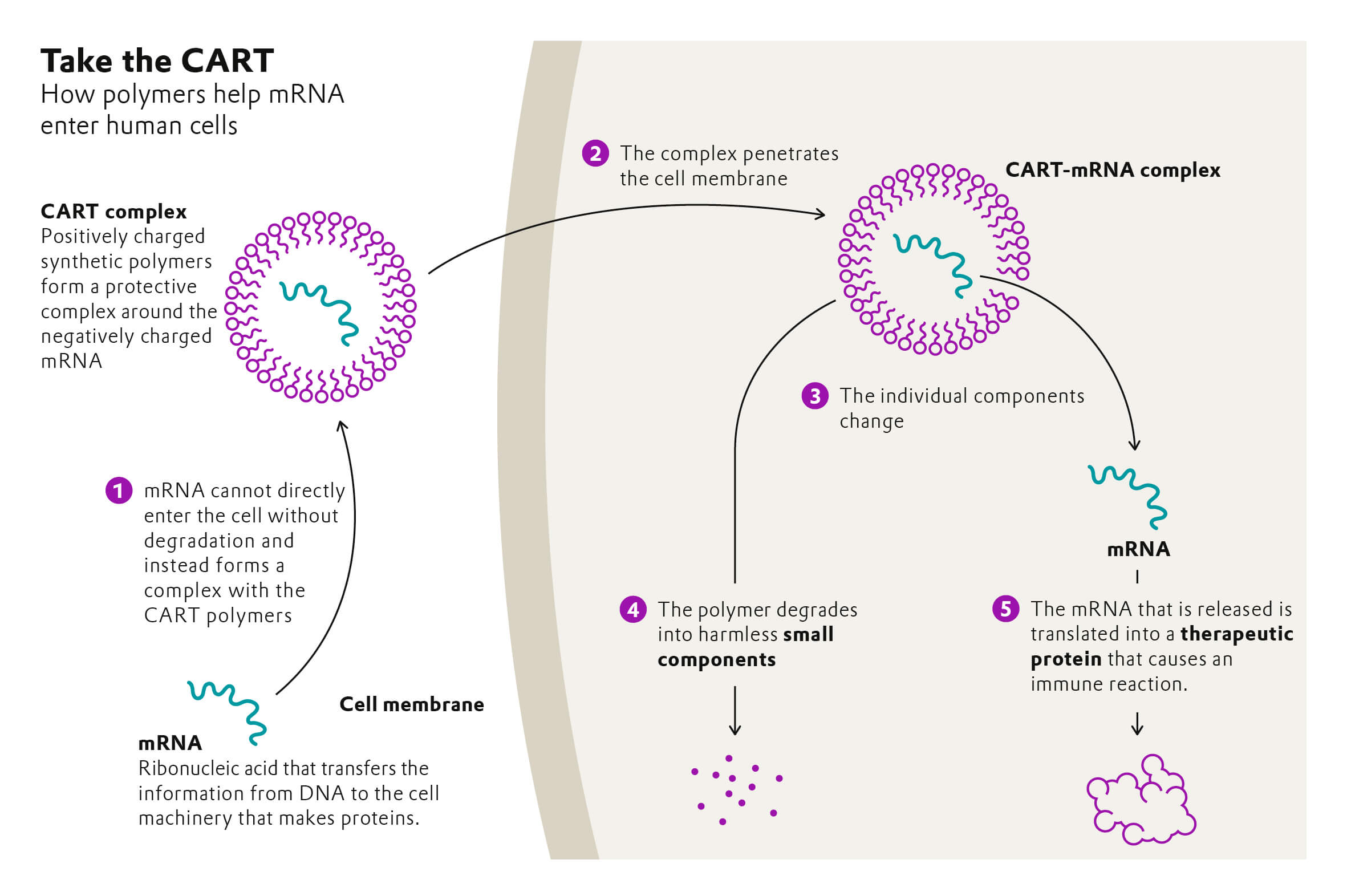

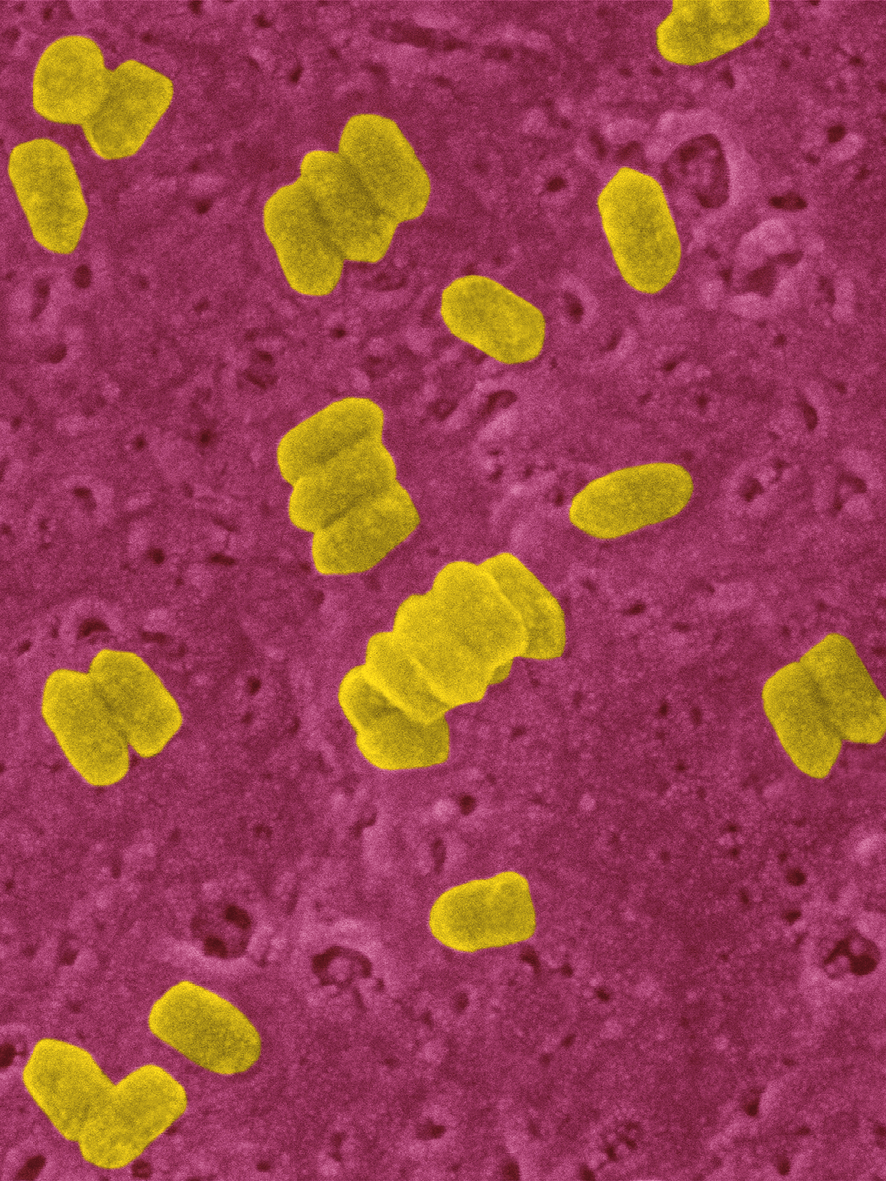

Reliable Transport

Special protection vehicle: Lipid nanoparticles envelop mRNA vaccines and enable their passage through the cell membrane.